Stainless steel filter cartridges play a crucial role in many filtration systems, particularly in industries where precision and durability are essential. These cartridges come in various ratings, measured in microns, to suit different filtration needs. The rating range, such as 0.5, 1, 2, 5, 10, 15, 20, 25, 30, 40, 50, 100, 150, and 200 microns, corresponds to the ability of the filter media to capture particles of specific sizes.

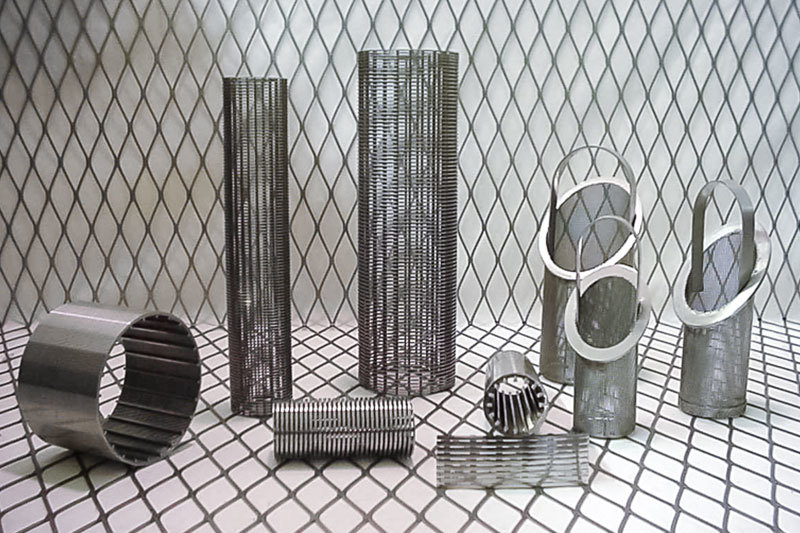

The most commonly used materials for these cartridges are SS 304, 304L, 316, and 316L stainless steel. These variants offer excellent corrosion resistance and are suitable for a wide range of applications. In more demanding conditions, materials like 310S (for high-temperature environments), 904L (known for high corrosion resistance), and Duplex 2205 / 2507 (offering both strength and corrosion resistance) are preferred.

In highly specialized applications, other metal materials such as titanium, nickel-based alloys, or copper alloys can also be utilized if stainless steel does not meet the required specifications.

The manufacturing process involves expert welding techniques to ensure the integrity of the cartridges. Years of experience in handling these metals and filter media enable us to deliver reliable and effective filtration solutions.

Stainless steel filter cartridges are designed to withstand challenging environments and varying fluid conditions. They are used in diverse industries such as pharmaceuticals, food and beverage, chemicals, and water treatment.

The choice of filter material and design depends on specific requirements such as particle size, fluid type, temperature, and chemical compatibility. This ensures optimal performance and longevity of the filtration system.

Regular maintenance and replacement of filter cartridges are crucial for consistent performance. Monitoring pressure differentials across the filter can indicate when cartridges need to be replaced.