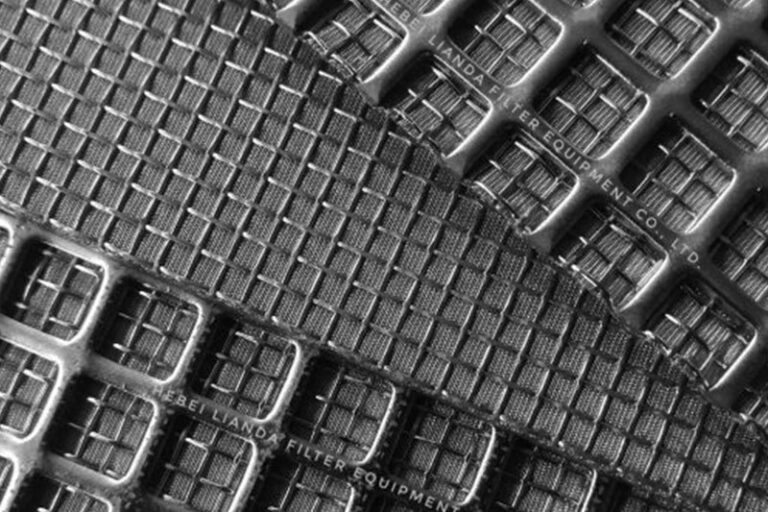

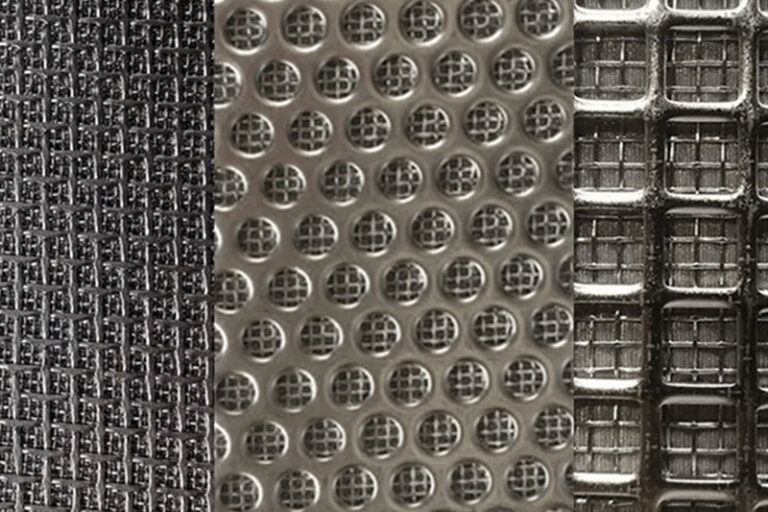

When it comes to high-temperature environments, stainless steel filters play a crucial role. The 310 and 310S stainless steel sintered wire mesh filter elements are designed to block particles using a specialized multi-layer mesh. This mesh traps contaminants effectively, making these filters perfect for surface-level filtration tasks.

These filters can handle extreme temperatures, especially thanks to the alloy’s unique composition. With a high chromium (25%) and silicon (0.6%) content, Alloy 310 is exceptionally resistant to corrosion in various conditions.

Here’s a breakdown of its performance:

- Under Oxidizing Conditions (Low Sulfur Content)

- Continuous Service: Up to 1050°C (1922°F)

- Peak Temperature: Up to 1100°C (2012°F)

- Under Oxidizing Conditions (High Sulfur Content)

- Maximum Temperature: 950°C (1742°F)

- In Low Oxygen Atmospheres (Low Sulfur Content)

- Maximum Temperature: 1000°C (1832°F)

- In Nitriding or Carburizing Atmospheres

- Maximum Temperature: 850 – 950°C (1562 – 1742°F)

Although Alloy 310 310S may not perform as well as other alloys like Alloy 600 or 800 in certain environments, it does outshine most heat-resistant stainless steels under similar conditions.

For even tougher conditions, consider nickel-based alloy filters, which excel in high-temperature and chemically harsh settings.

In summary, stainless steel filters are essential for filtering particles in extreme conditions, offering durability and reliability where ordinary filters may fail.