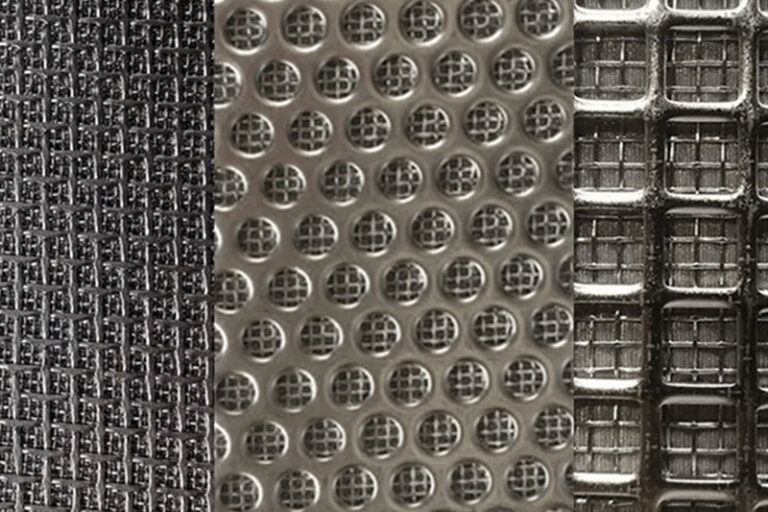

In filtration systems, sintered wire mesh often includes wire cloth, Dutch weave filter mesh, and perforated metal sheet. However, metal fiber web (sintered metal fiber felt) can also be sintered together with wire mesh.

Typically, the sintered metal fiber felt is combined with a single layer of wire mesh on one or both sides to reinforce it. This combination is used in cylindrical or disc-shaped filter elements like polymer melt filter discs or dedusting filter cartridges.

The wire mesh is crucial for strengthening the metal fiber felt. Filter ratings for wire mesh are limited to around 1 micron due to its structure and pore size. In contrast, sintered metal fiber felt can achieve absolute ratings of 1 micron or higher, especially for air and gas filtration.

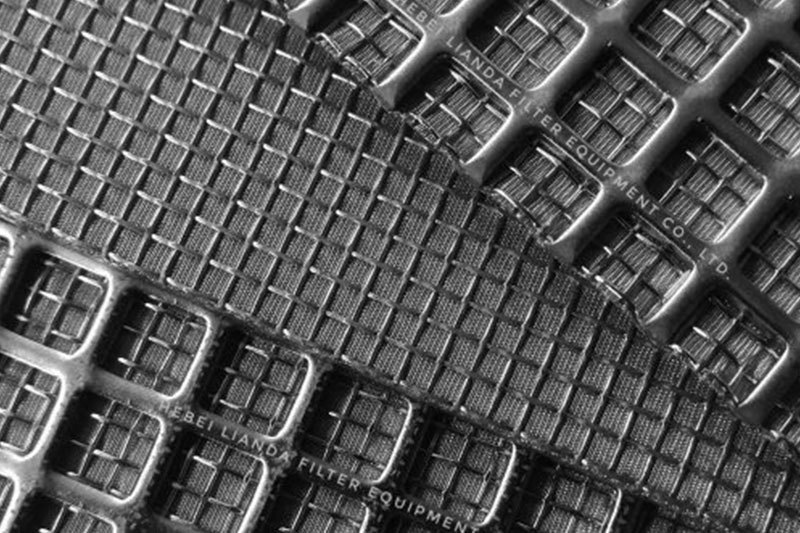

Keeper Filter has developed a customized product for critical applications that require both higher filtration ratings and strength: a composite of sintered wire mesh with sintered metal fiber felt.

The composite consists of multiple layers of wire mesh with sintered metal fiber felt as the filtration layer. The wire mesh layers provide support and protection for the super-fine metal fiber web. This composite is particularly suitable for cylindrical filter elements like cartridges because it is self-supporting and has sufficient mass for TIG welding.