Stainless steel 904L sintered wire mesh is crafted from a super austenitic stainless steel material known for its ability to withstand moderate to highly corrosive environments. This material contains high levels of chromium, nickel, copper, and molybdenum, providing exceptional resistance against chloride stress corrosion cracking, pitting, and various acids.

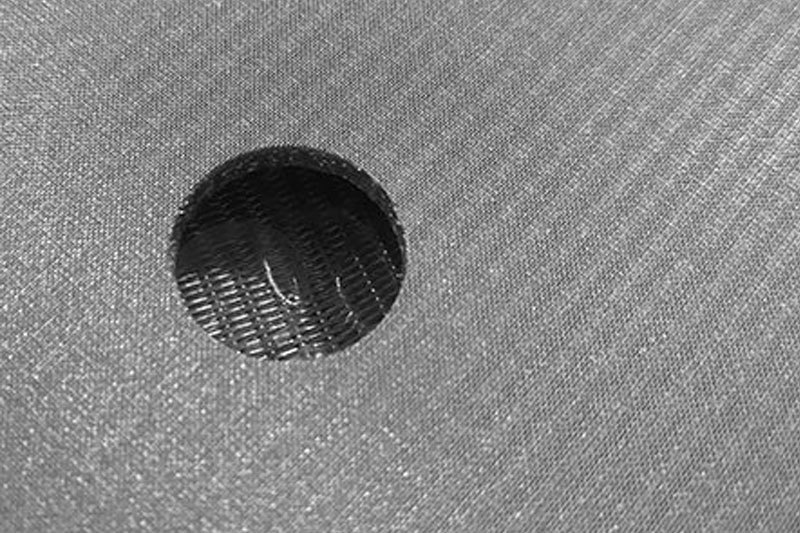

904L stainless steel wire mesh comes in a variety of weaving patterns and micron ratings. Perforated metal sheets made from 904L stainless steel can be customized in terms of thickness, hole shape, size, and pitch to create tailored sintered wire mesh solutions.

Compared to Hastelloy C sintered wire mesh, 904L is a more cost-effective choice for applications that don’t require extreme corrosion resistance.

Applications of 904L Sintered Mesh and Filters in Seawater and Chemical Processing

The primary uses of 904L sintered wire mesh and filter elements are in seawater-related filtration (such as ballast water treatment and offshore oil and gas processes) and chemical processing (including pharmaceutical applications). Commonly produced 904L filter elements include sintered wire mesh filter discs, plates, and filter tube screens, which are integral components in filtration equipment like agitated nutsche filters, automatic self-cleaning filters, basket strainers, and large-scale chromatography columns.