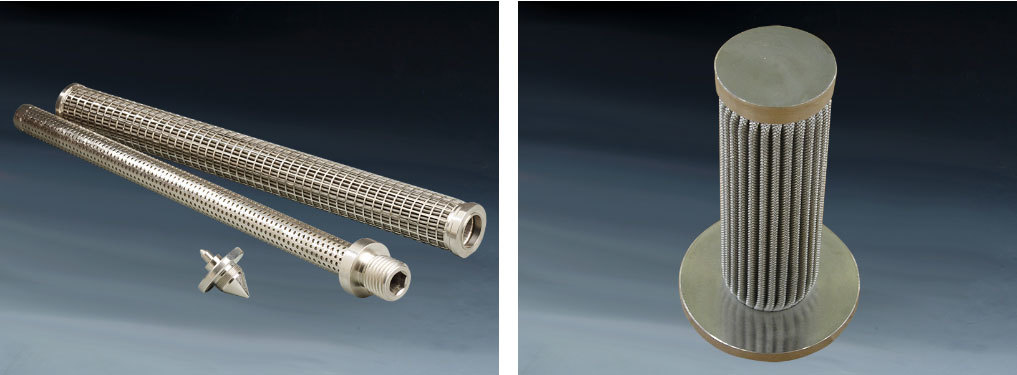

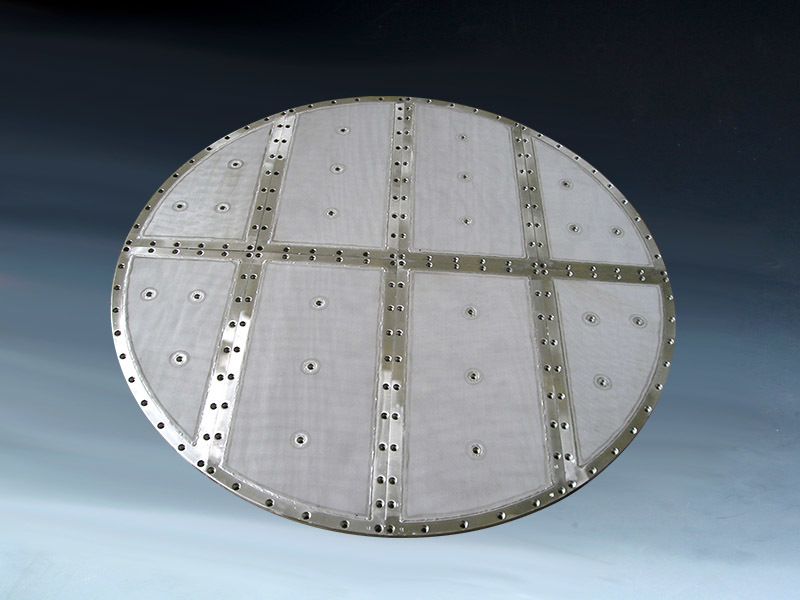

Pleated filter element

There are two types of filter materials available: stainless steel sintered fiber web and stainless steel woven wire mesh.

The effective filtration area per 10 inches of length differs between these two materials:

– For pleated cartridges: 1.40 square feet (0.13 square meters)

– For cylindrical cartridges: 0.55 square feet (0.05 square meters)

Description

Filter Materials

- Stainless Steel Sintered Fiber Web

- Stainless Steel Woven Wire Mesh

Effective Filtration Area (per 10 inches of length)

- Pleated Cartridge: 1.40 square feet (0.13 square meters)

- Cylindrical Cartridge: 0.55 square feet (0.05 square meters)

Gaskets and O-rings

EPDM is the standard gasket material. Other options include Nitrile, PTFE, silicone, Viton, and PTFE-coated Viton, available upon request or for specific processes.

Cartridge End Fittings

Various cartridge end fittings are available, including 226 fitting, 222 fitting, double open-ended fitting, single open-ended fitting, threaded end fitting, 1-inch, and 1/2-inch NPT.

Main Filter Material Introduction

♦Stainless Steel Sintered Fiber Web

Stainless steel sintered fiber web is a multipore deep filter media sintered with stainless steel fiber at high temperatures. It offers high porosity, a large filter area, good dirt holding capacity, and can be chemically cleaned and reused.

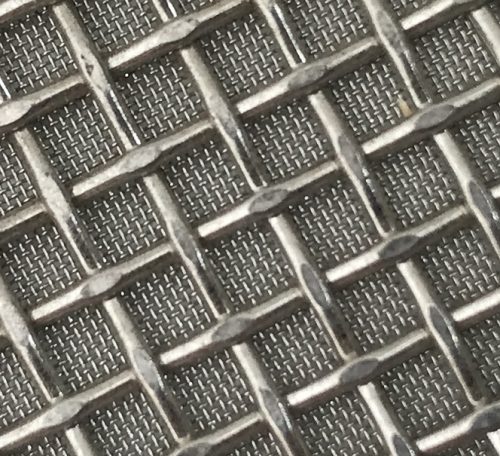

♦Stainless Steel Woven Wire Mesh

Stainless steel woven wire mesh filter elements have good strength, durability, ease of cleaning, high temperature resistance, and are cost-effective.

Filter Rating and Size

Filter ratings range from 3 to 200 microns and can be customized based on customer requirements.

Application Range

These pleated filter elements are widely used for filtering high molecular polymers, pharmaceuticals, hydraulic oil, water treatment, hot gases, and more.