Showing 1–16 of 17 results

-

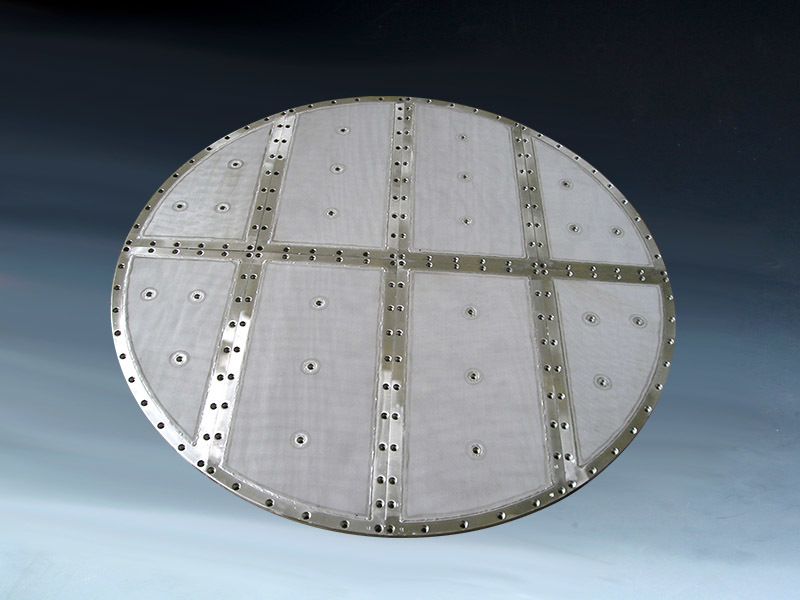

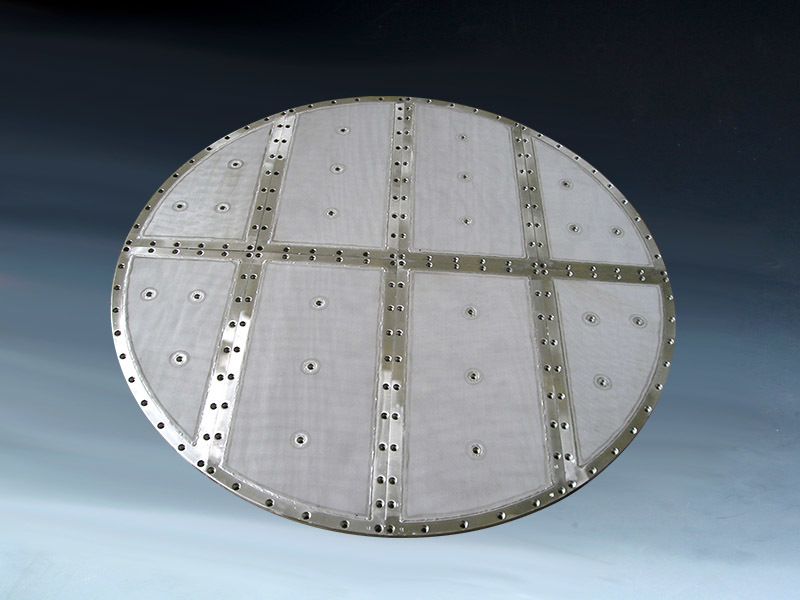

The filter material used in Disc Filters is a special type of layered wire cloth that has been sintered together. This filter can trap particles ranging in size from 0.5 to 200 microns and comes in sizes ranging from 200mm to 3000mm in diameter. Disc filters equipped with this layered wire cloth filter have strong durability, provide precise filtration, boast a long lifespan, and can be cleaned and reused multiple times.

-

DP-01 Polypropylene (PP) filter cartridge is crafted from top-notch Chinese or imported PP membrane, ensuring a blend of affordability, high flow, and relatively strong retention capacity. DP-01 stands out as the go-to choice for micro-porous precision filtration needs.

-

DP-02 high-precision polypropylene (PP) filter cartridge is crafted from a multi-layer gradient rating PP membrane, representing an enhanced version of the DP-01 model.

-

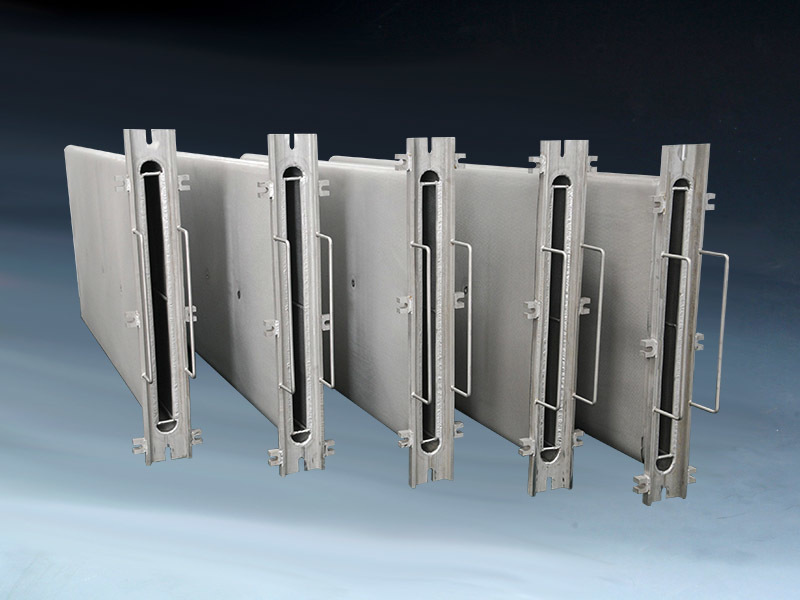

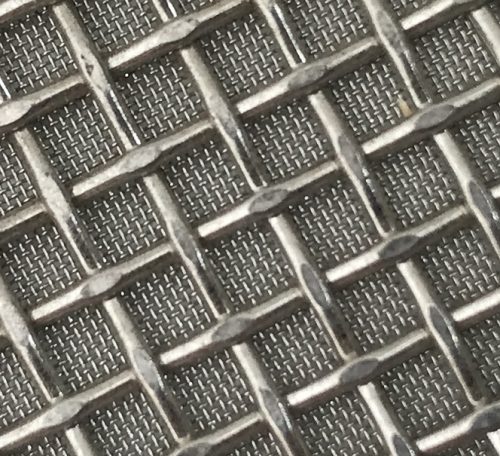

The filter materials used in basket filters include stainless steel perforated sheets, stainless steel woven wire mesh, and stainless steel sintered wire cloth. We can customize the external dimensions and filter ratings based on customer requirements.

-

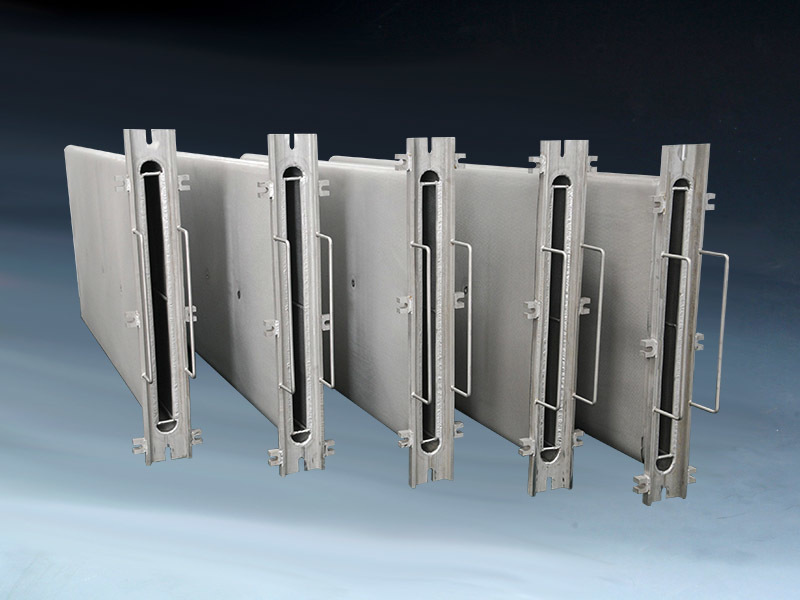

The filter housing is composed of a vertical cylindrical body, a sealing cap, a flange, a connection plate, and other components. Inside the housing, you can choose different filter elements with varying filtration rates. The connection methods can include various shapes such as bayonet and threaded connections.

-

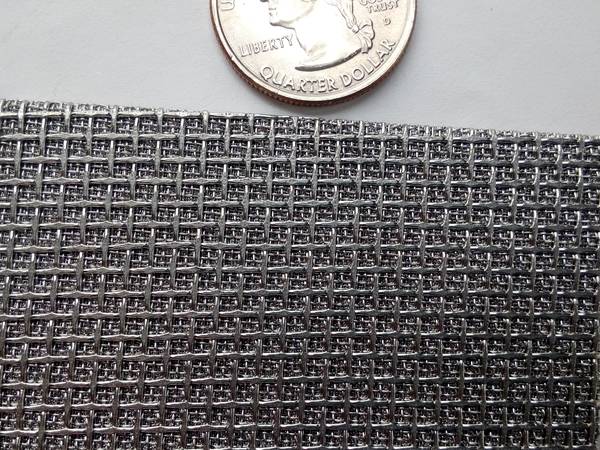

Keeper offers high-quality filtration and sieving mesh solutions for industries like oil and gas, food processing, petrochemical, chemical, soil cleaning, water treatment, and refineries. With a wide range of mesh options from 1 micron to 12,500 mm, we provide durable and customizable filtration solutions using premium materials, including stainless steel and exotic alloys. Find the perfect filtration mesh for your application today.

-

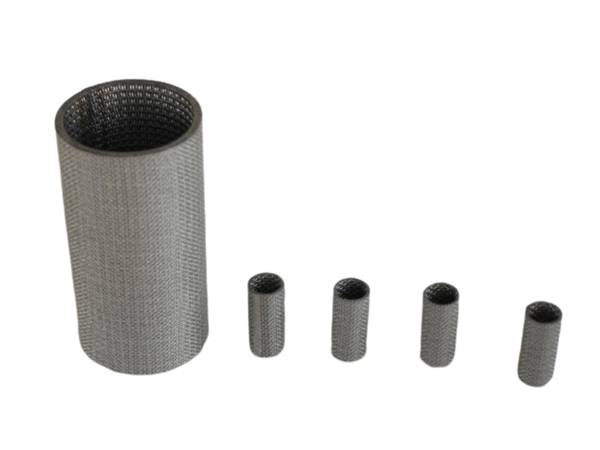

There are two types of filter materials available: stainless steel sintered fiber web and stainless steel woven wire mesh.

The effective filtration area per 10 inches of length differs between these two materials:

– For pleated cartridges: 1.40 square feet (0.13 square meters)

– For cylindrical cartridges: 0.55 square feet (0.05 square meters)

-

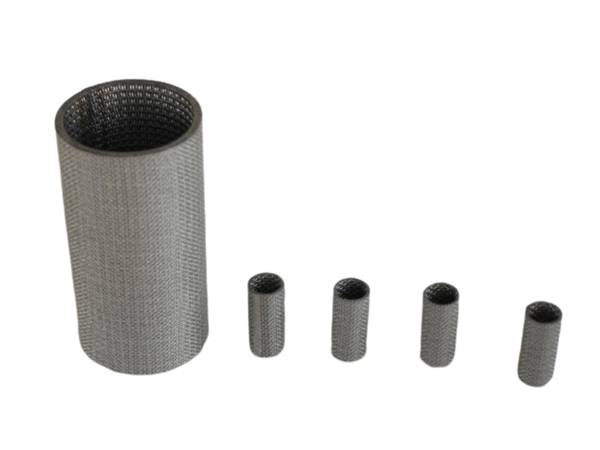

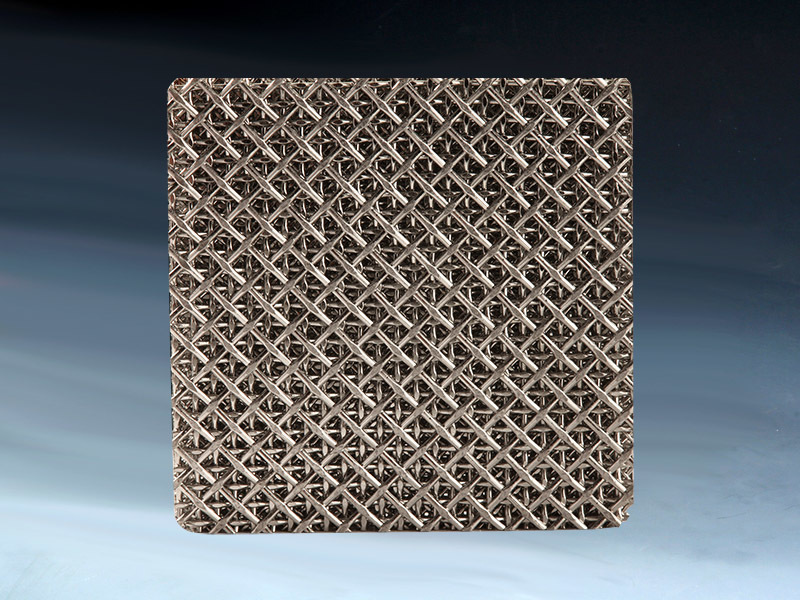

Sintered mesh filter elements are made from five layers of sintered wire cloth, offering filtration ratings from 0.5 microns to 200 microns.

Effective Filtration Area (per 10 inches of length)

Pleated cartridge: 1.40 square feet (0.13 square meters)

Cylindrical cartridge: 0.55 square feet (0.05 square meters)

Sintered mesh filter elements use a special process to create a layered structure using wire cloth. They provide precise filtration across a range of sizes, ensuring efficient removal of particles from fluids or gases. The pleated design maximizes the filter area, while cylindrical cartridges offer a compact filtration solution.

-

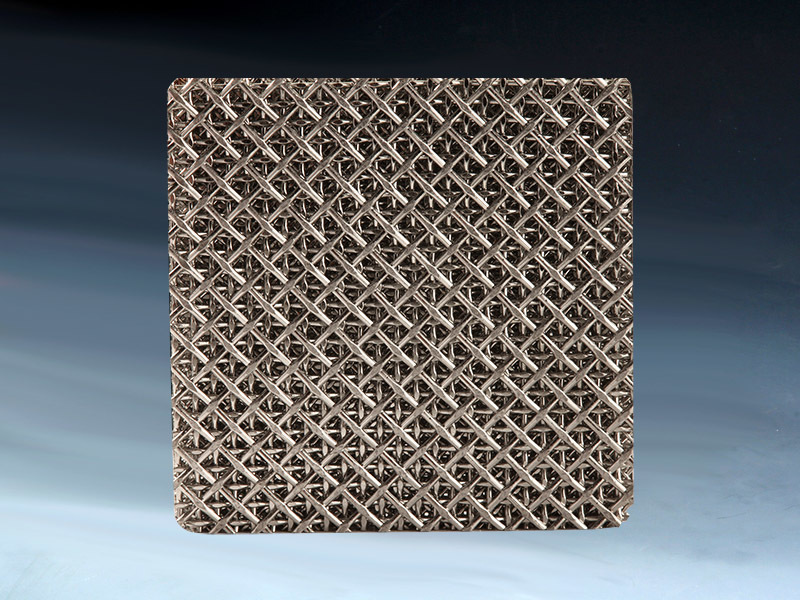

High-strength sintered mesh laminates made from stainless steel or alloys, available in single or multiple layers. Custom designs tailored for stability, strength, and effective filtration across various industries.

-

High-quality sintered metal filter cartridges made from stainless steel wire mesh offer excellent filtration with high strength, smooth pores, and resistance to high temperatures, making them ideal for industries like food, chemical, and aerospace.

-

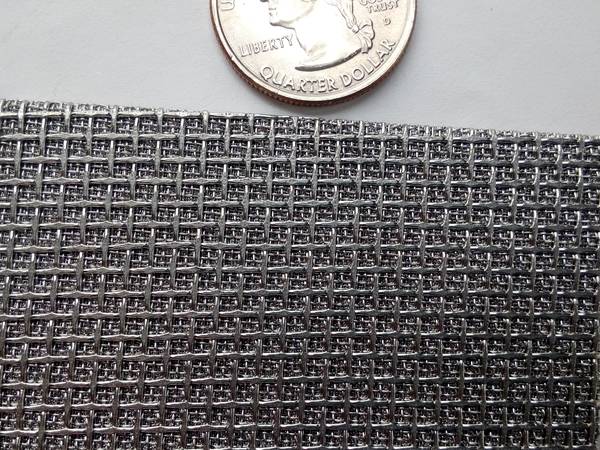

Explore our five-layer sintered mesh made from stainless steel, featuring high strength, heat resistance up to 600°C, and precise filtration from 1 to 200 microns. Ideal for filtration in water treatment, gas distribution, and industrial applications. Custom sizes available.

-

Other varieties of metal filter elements include: folded wire mesh filter cartridges, tubular wire mesh filter cartridges, tailor-made wire mesh filter elements, and wedge wire filter elements.

-

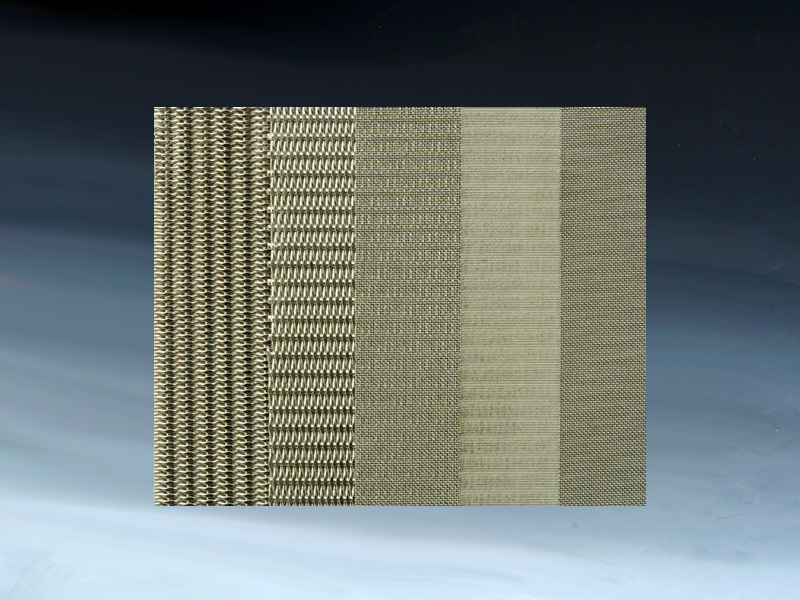

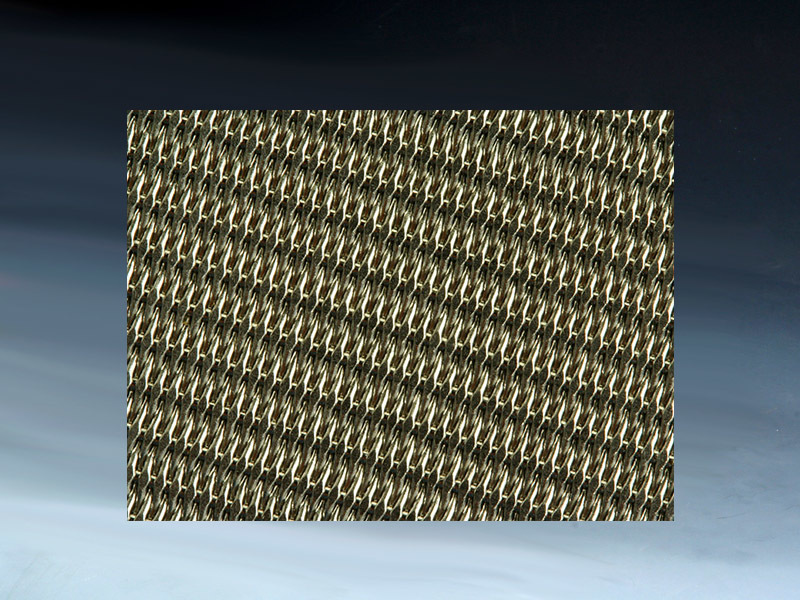

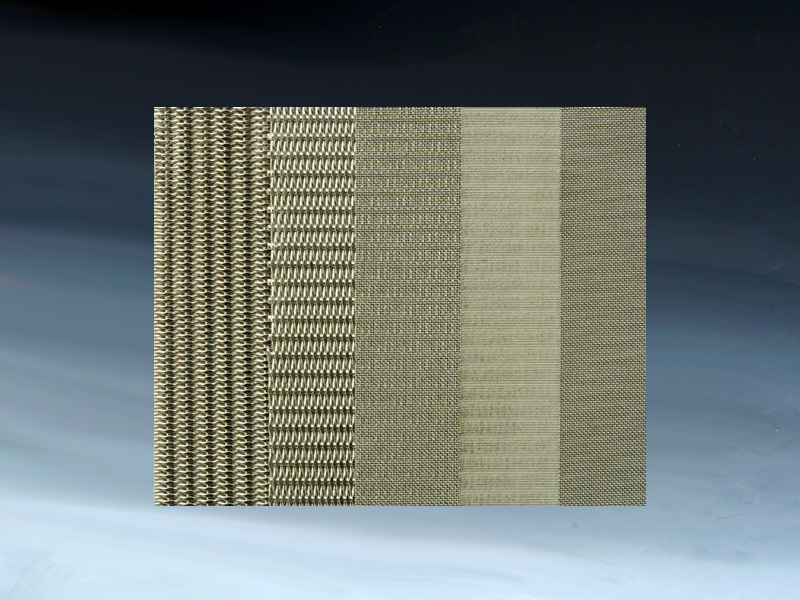

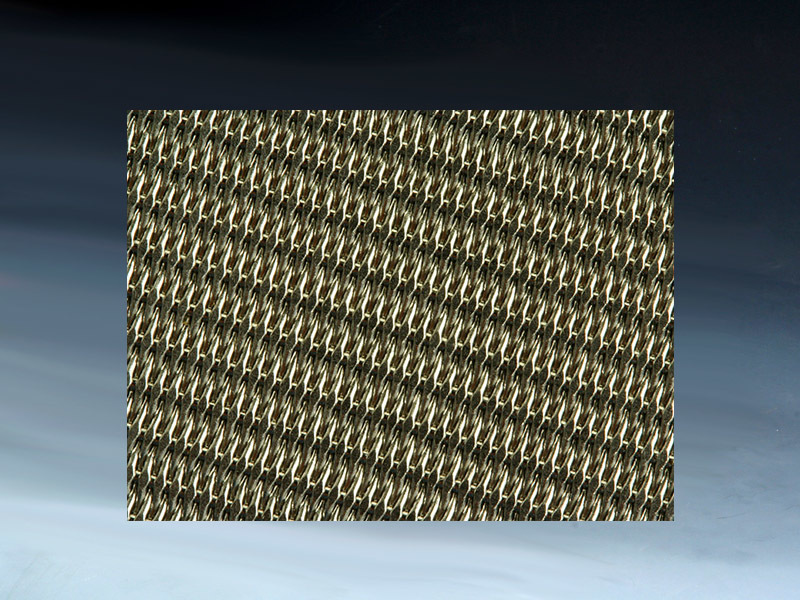

This is a widely used type of filter made from a combination of five layers of stainless steel wire mesh. The layers are joined together and transformed into a porous product by a process involving vacuum sintering, compression, and calendaring. This filter is versatile and has broad applications. Specifications available upon request.

-

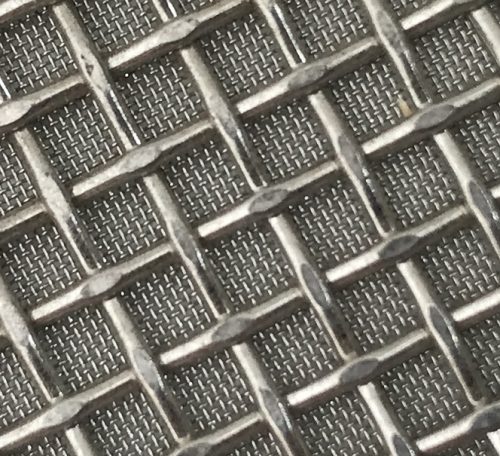

This type of mesh is created by sintering together multiple layers of simple woven square mesh. Because of the large openings between the mesh strands, the sintered mesh allows fluids to pass through easily, resulting in good permeability, low resistance, and high flow rates.

-

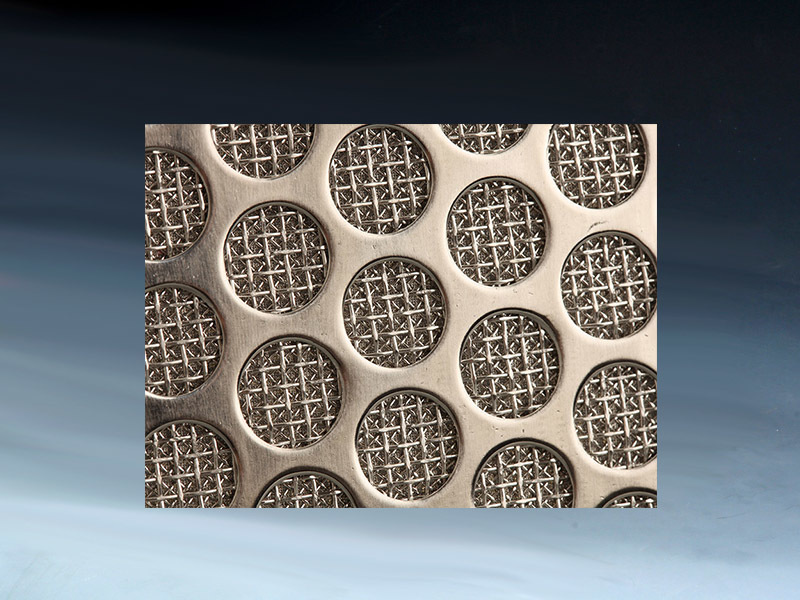

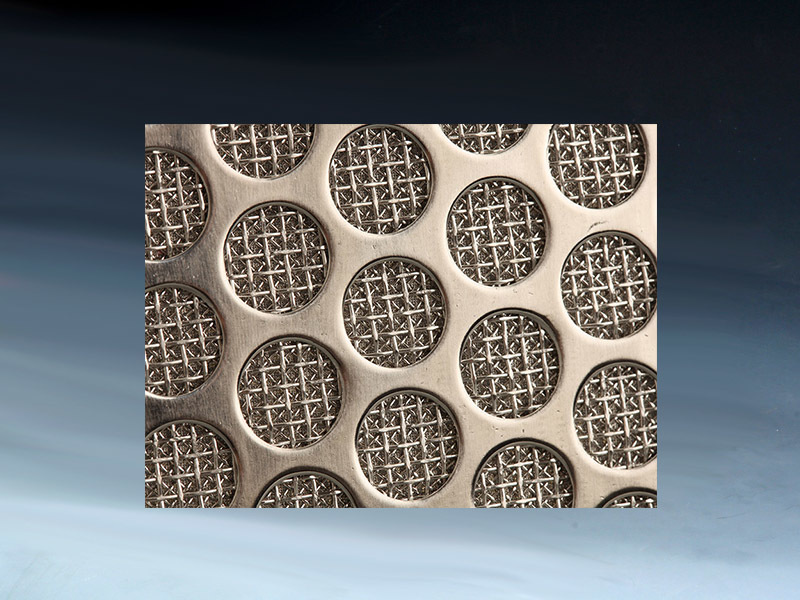

This filter is made by pressing a plate with layers of stainless steel mesh. The plate adds extra strength, making it useful in various industries like food, drinks, and water treatment.

-

Type D sintered wire mesh is created by layering 2 or 3 sheets of plain Dutch woven wire mesh with the same hole size. These layers are then vacuum sintered, expanded, and rolled flat. This process results in a mesh with consistent pore size and reliable airflow.