Sintered mesh filter element

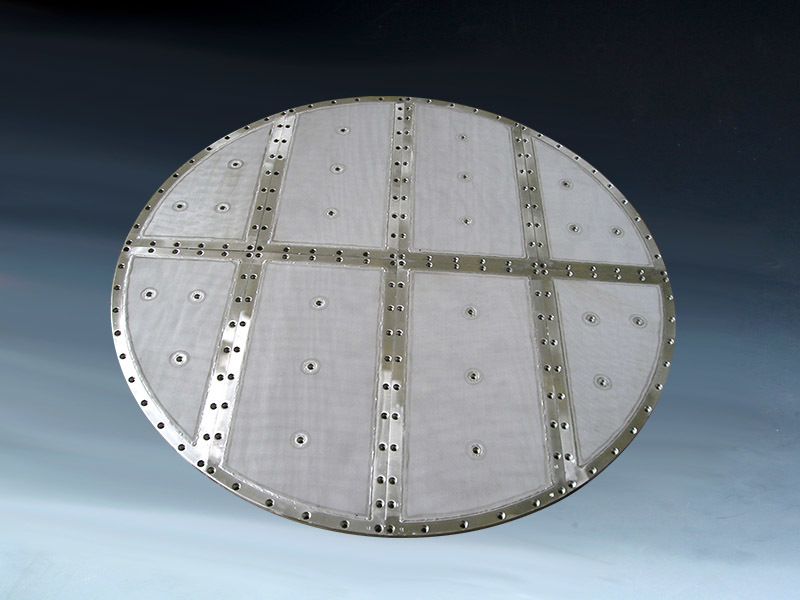

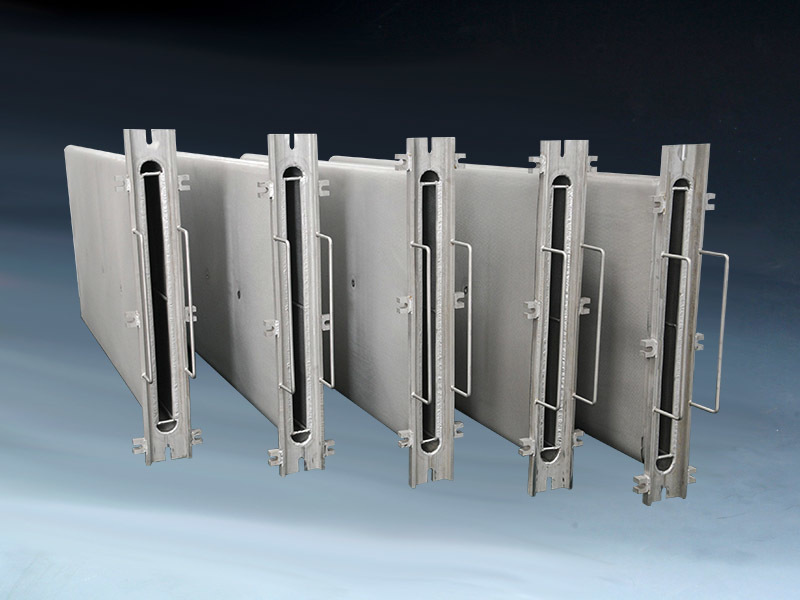

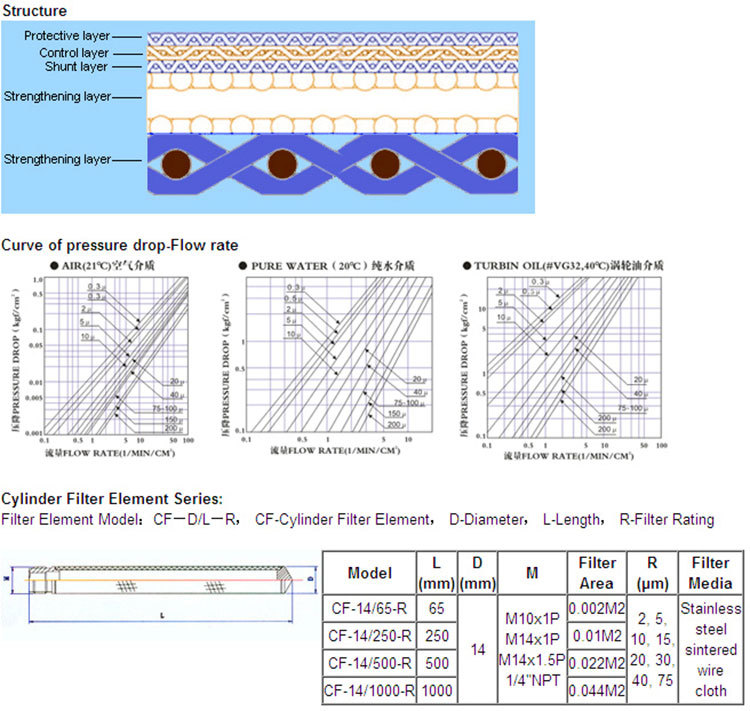

Sintered mesh filter elements are made from five layers of sintered wire cloth, offering filtration ratings from 0.5 microns to 200 microns.

Effective Filtration Area (per 10 inches of length)

Pleated cartridge: 1.40 square feet (0.13 square meters)

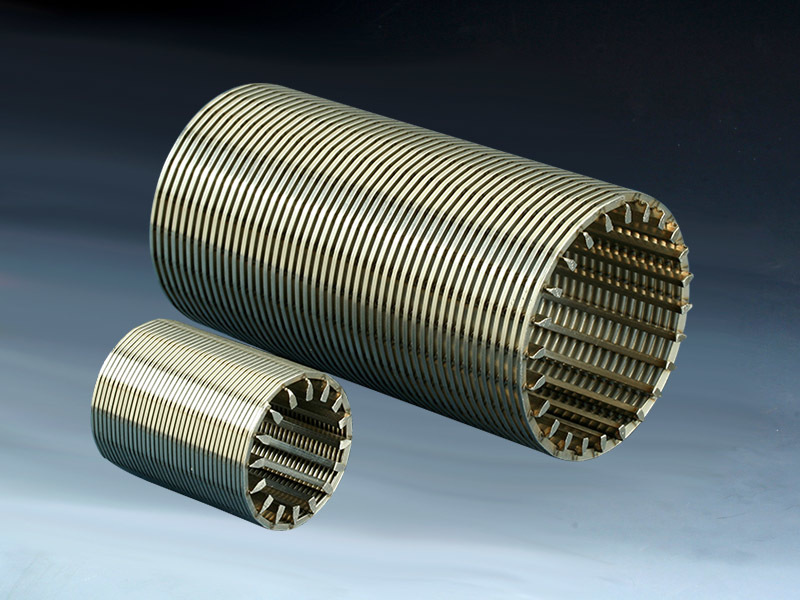

Cylindrical cartridge: 0.55 square feet (0.05 square meters)

Sintered mesh filter elements use a special process to create a layered structure using wire cloth. They provide precise filtration across a range of sizes, ensuring efficient removal of particles from fluids or gases. The pleated design maximizes the filter area, while cylindrical cartridges offer a compact filtration solution.

Description

Sintered Mesh Filter Element

Filter Information

Sintered mesh filter elements are constructed using a Five-Layer Sintered Wire Cloth, offering filtration ratings from 0.5 microns to 200 microns.

Effective Filtration Area (per 10 inches of length)

- Pleated Cartridge: 1.40 square feet (0.13 square meters)

- Cylindrical Cartridge: 0.55 square feet (0.05 square meters)

Gaskets and O-rings

EPDM is the standard gasket material, but options like Nitrile, PTFE, silicone, Viton, and PTFE-coated Viton are available upon request or for specific processes.

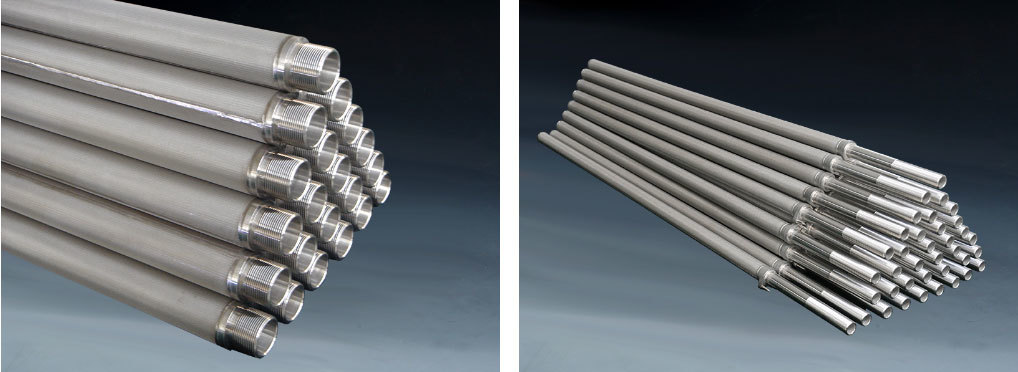

Cartridge End Fittings

Various cartridge end fittings are offered, including 226 fitting, 222 fitting, double open-ended fitting, single open-ended fitting, threaded end fitting, 1-inch, and 1/2-inch NPT.

Key Features of Sintered Mesh Filter Element

The Five-Layer Sintered Wire mesh consists of stainless steel wire mesh layers sintered together under vacuum. Cylinder filter elements made with this technology provide fine micron filtering, excellent permeability, high strength, easy cleaning, good corrosion resistance, durability, and do not leach materials during operation.

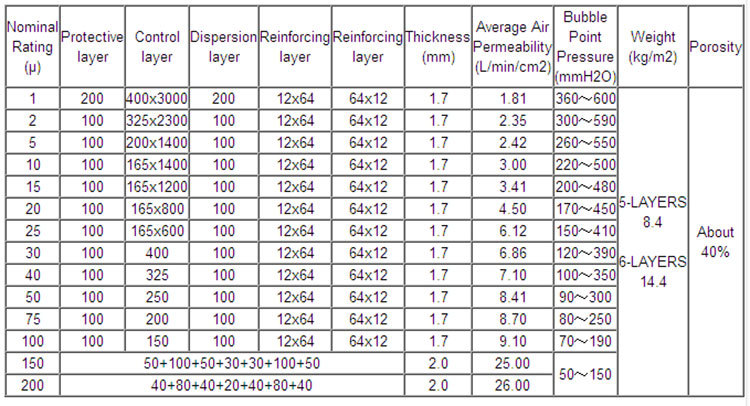

Main Technical Index of Sintered Metal Wire Cloth

Keeper’s Sintered Mesh Filter Element

For the past 18 years, Keeper’s experienced technical team has been providing specialized metal filter technology and design advice to customers from diverse backgrounds, tailoring solutions to meet their unique customization needs. We offer customized production with a wide range of specifications and shapes available for customization.

Applications of Sintered Mesh Filter Element

Keeper’s sintered mesh filter elements are used extensively for filtering polyester, oil products, chemicals, and pharmaceuticals. They are also highly effective in filtering pure water and gases, meeting various filtration requirements across different industries.