Sintered Mesh Laminate

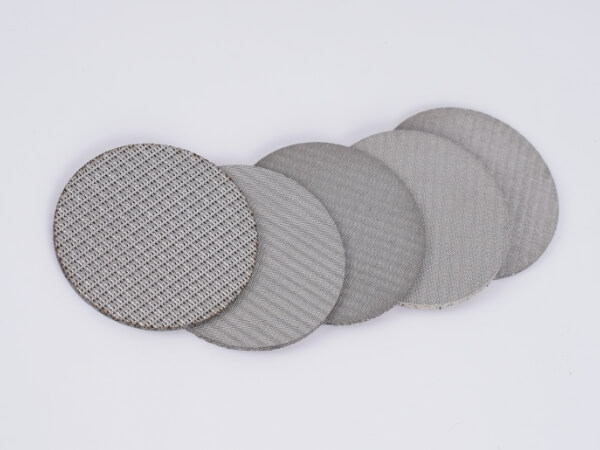

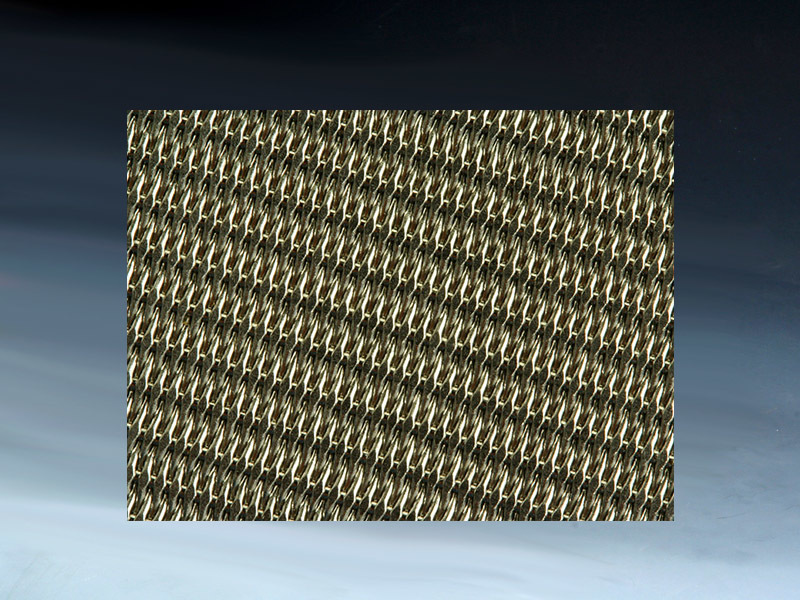

High-strength sintered mesh laminates made from stainless steel or alloys, available in single or multiple layers. Custom designs tailored for stability, strength, and effective filtration across various industries.

Description

Single/Multiple Layer of Sintered Mesh Laminates

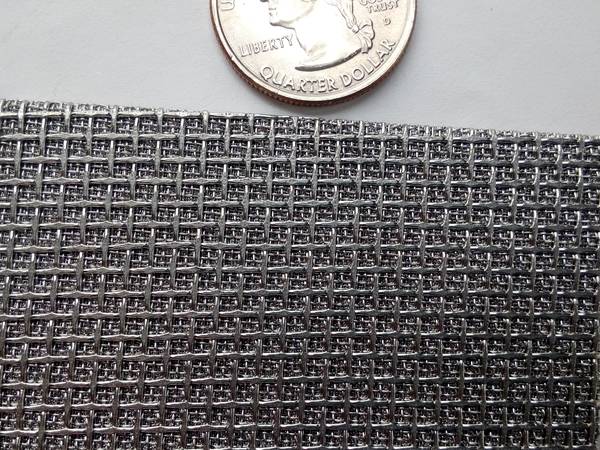

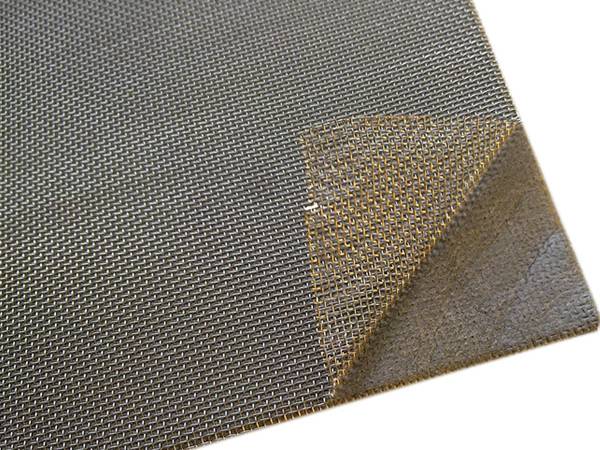

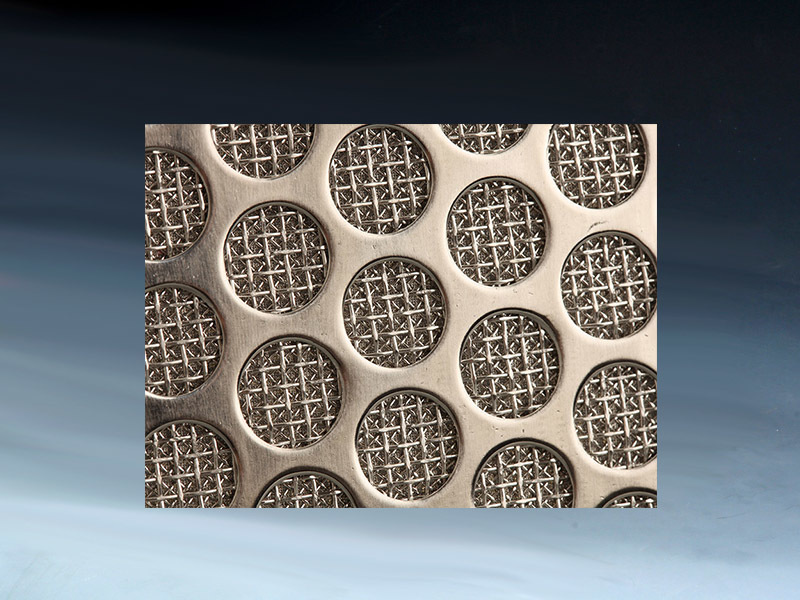

Sintered mesh laminate is a type of strong, porous material. It is made using stainless steel or other metal alloys. By using a special process called diffusion-bonding, one or more layers of woven wire mesh are permanently joined together. This makes it stronger and more stable than regular wire mesh. Because of these qualities, it’s commonly used as a filter in various industries.

|

|

|

Based on the number of layers, sintered mesh laminates can be categorized into two types: single-layer sintered mesh laminate and multi-layer sintered mesh laminate.

Single Layer Sintered Mesh Laminate

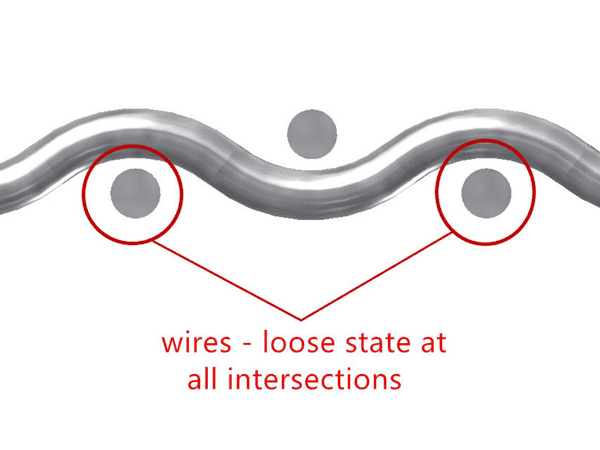

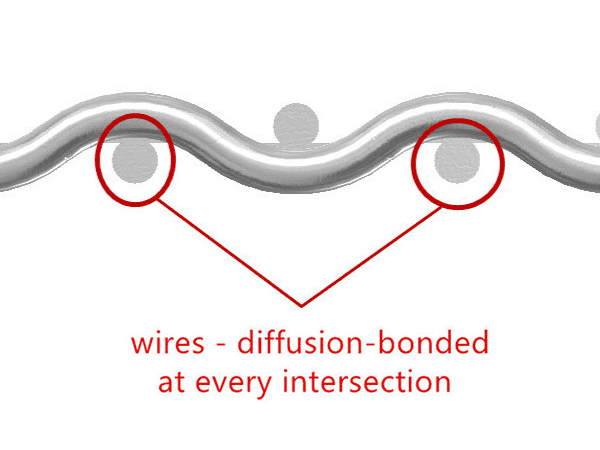

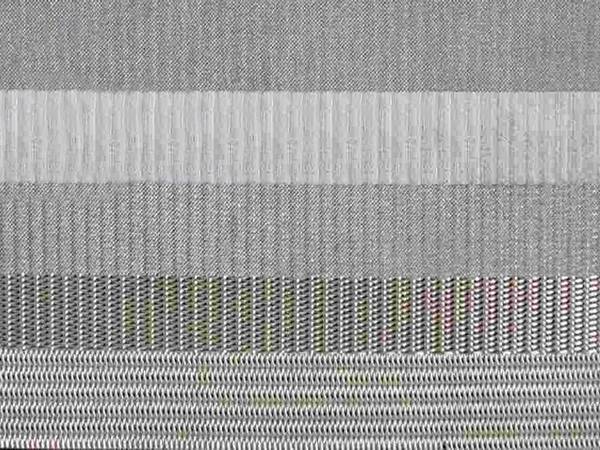

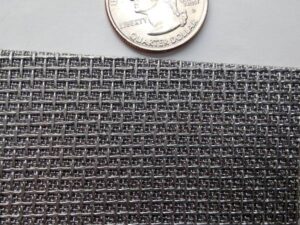

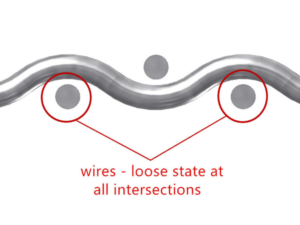

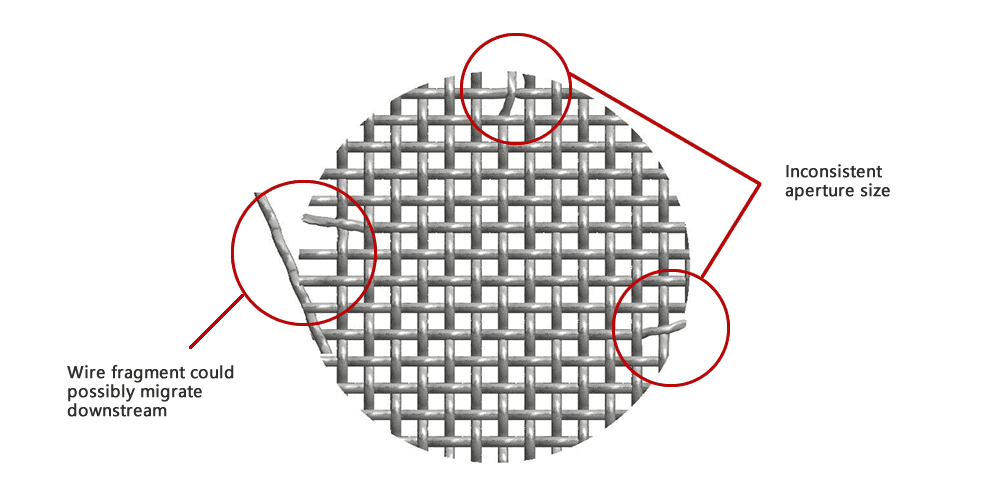

We all know that a single layer of woven wire mesh, though widely used, has some drawbacks. The edges can start to fray, and the wires can move within the weave. This not only changes the overall structure but also affects the filter’s performance, as the pore size can be altered.

The sintering process, which uses heat and pressure, forms strong molecular bonds at every point where the wires cross over and under each other in the wire mesh. This process greatly improves the mesh’s mechanical strength and filtration abilities.

For example, if we look at a 10 × 10 plain weave woven wire mesh, you can clearly see the difference in the cross-section before and after the sintering process.

|

|

|

Specification – single layer sintered mesh laminate

| Product Code | Filter Rating (µm) | Structure | Wire Diameter (inch) | Overall Thickness (inch) | Weight / sq.ft (kg) |

|---|---|---|---|---|---|

| SLSM-01 | 5 | 200 × 1400 | 0.0028 | 0.0058 | 0.1135 |

| SLSM-02 | 178 | 80 × 0.0055″ | 0.0055 | 0.0088 | 0.0772 |

| SLSM-03 | 234 | 60 × 0.0075″ | 0.0075 | 0.0125 | 0.1090 |

| SLSM-04 | 279 | 50 × 0.009″ | 0.009 | 0.0144 | 0.1317 |

| SLSM-05 | 380 | 40 × 0.01″ | 0.01 | 0.0147 | 0.1271 |

| SLSM-06 | 540 | 30 × 0.012″ | 0.012 | 0.0155 | 0.1362 |

| SLSM-07 | 860 | 20 × 0.016″ | 0.016 | 0.0238 | 0.1589 |

| SLSM-08 | 2460 | 8 × 0.028″ | 0.028 | 0.0397 | 0.1907 |

Multi-Layer Sintered Mesh Laminate

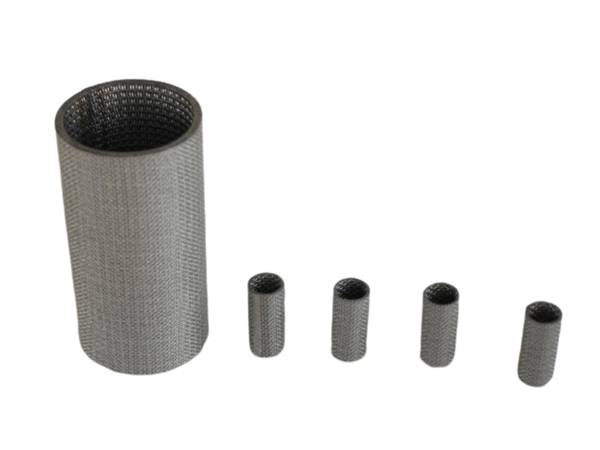

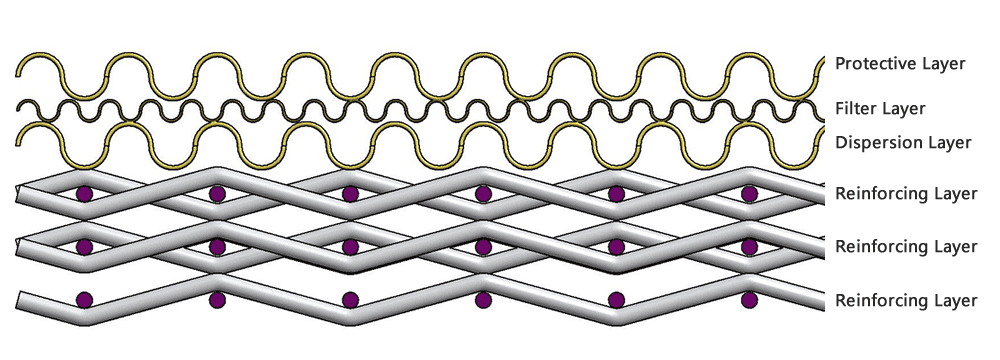

With layers ranging from 2 up to more than 25, multi-layer sintered mesh laminates offer greater strength for filters and tough environment applications. A single layer of wire mesh used for filtration, separation, or sifting often lacks strength and can be easily damaged. By adding more layers through the sintering process, the mesh gains the ability to handle high pressure, making it a deeper and stronger filter material.

Starting with a five-layer sintered mesh as the base, a six-layer sintered mesh is created by adding an extra layer of 12 mesh. The six-layer sintered mesh laminate is versatile and can be used for filtering, washing, and drying, making it ideal for three-in-one medical filter plates, which come in two forms: split type and one-piece type.

|

|

|

|

Specification – two and three layers sintered mesh laminate

| Code | Layer Number | Structure | Filter Rating (µm) | Overall Thickness (mm) | Weight / sq.ft (kg) |

|---|---|---|---|---|---|

| SML-201 | 2 | 100 × 0.0045″ / 200 × 1400 | 5 | 0.2286 | 0.1135 |

| SML-202 | 2 | 10 × 0.025″ / 325 × 0.0014″ | 44 | 0.9144 | 0.2088 |

| SML-203 | 2 | 60 × 0.0075″ / 325 × 0.0014″ | 44 | 0.36576 | 0.1271 |

| SML-204 | 2 | 10 × 0.025″ / 250 × 0.0016″ | 55 | 0.9398 | 0.2088 |

| SML-205 | 2 | 10 × 0.025″ / 200 × 0.0021″ | 74 | 0.9525 | 0.2179 |

| SML-206 | 2 | 30 × 0.012″ / 150 × 0.0026″ | 105 | 0.4953 | 0.1680 |

| SML-207 | 2 | 10 × 0.025″ / 150 × 0.0026″ | 105 | 0.4953 | 0.2177 |

| SML-208 | 2 | 60 × 0.0075″ / 100 × 0.0045″ | 140 | 0.51308 | 0.1725 |

| SML-209 | 2 | 10 × 0.025″ / 100 × 0.0045″ | 140 | 0.96266 | 0.2542 |

| SML-210 | 2 | 20 × 0.016″ / 20 × 0.016″ | 864 | 0.8128 | 0.3178 |

| SML-301 | 3 | 60 × 0.0075″ / 325 × 2300 / 60 × 0.0075″ | 2 | 0.56642 | 0.2633 |

| SML-302 | 3 | 60 × 0.0075″ / 200 × 1400 / 60 × 0.0075″ | 5 | 0.62738 | 0.2906 |

| SML-303 | 3 | 60 × 0.0075″ / 165 × 1400 / 60 × 0.0075″ | 10 | 0.72136 | 0.2906 |

| SML-304 | 3 | 60 × 0.0075″ / 165 × 800 / 60 × 0.0075″ | 15 | 0.62738 | 0.2679 |

| SML-305 | 3 | 60 × 0.0075″ / 80 × 700 / 60 × 0.0075″ | 25 | 0.86106 | 0.2838 |

| SML-306 | 3 | 60 × 0.0075″ / 325 × 0.0014″ / 60 × 0.0075″ | 44 | 0.62484 | 0.2361 |

| SML-307 | 3 | 60 × 0.0075″ / 250 × 0.0016″ / 60 × 0.0075″ | 55 | 0.6223 | 0.2361 |

| SML-308 | 3 | 60 × 0.0075″ / 200 × 0.0021″ / 60 × 0.0075″ | 74 | 0.64262 | 0.2452 |

| SML-309 | 3 | 60 × 0.011″ / 100 × 0.0045″ / 200 × 0.0021″ | 74 | 0.72898 | 0.1998 |

| SML-310 | 3 | 60 × 0.0075″ / 150 × 0.0026″ / 60 × 0.0075″ | 105 | 0.65786 | 0.2497 |

| SML-311 | 3 | 60 × 0.0075″ / 100 × 0.0045″ / 60 × 0.0075″ | 140 | 0.76708 | 0.2815 |

Specification – Four-layer sintered mesh laminate

| Product Code | Structure | Filter Rating (µm) | Thickness (mm) | Weight (kg/m2) | Porosity (%) |

|---|---|---|---|---|---|

| FLSM-01 | 60 / filter layer / 40 / 20 | 2 – 200 | 1.0 | 4.4 | 44 |

| FLSM-02 | 40 / filter layer / 20 / 16 | 2 – 200 | 1.7 | 6.2 | 54 |

Note:

1. Porosity takes that of 20 mesh as criteria.

2. The filter layer is taken as per your demand.

Six-layer sintered mesh laminate

- Filter rating: Ranges from 1 µm to 100 µm.

- Total thickness: 3.5 mm.

- Standard size: 1000 mm × 1200 mm.

Seven-layer sintered mesh laminate

- Structure: 50 / filter layer / 40 / 20 / 40 / filter layer / 50.

- Thickness: 2 mm.

- Filter rating: Between 2 µm and 150 µm.

- Weight: 7.4 kg per square meter.

- Porosity: 58%.

Material Options:

Made from stainless steel such as SUS 304, SUS 304L, SUS 316, and SUS 316L. Other alloy options are also available based on your needs.

Features:

- Very strong and stable.

- Allows fluids and gases to pass through easily.

- Resistant to rust and corrosion due to stainless steel material.

- Can be shaped into other filter types for deeper filtering tasks.

- Provides precise filtering performance.

- Simple to clean and can be reused multiple times.

|

|

|

Applications

- Filtration: Used in hot gas filter elements and process filter elements.

- Fluidization: Ideal for fluidized beds, air slides, air flow devices, and aerators.

- Other Uses: Helps reduce noise (sound dampening), creates bubbles in air diffusers, and prevents flames from spreading or causing explosions.