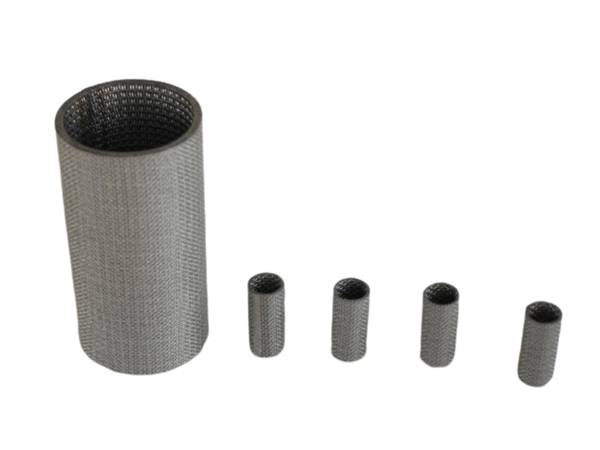

Sintered Metal Filter Cartridge

High-quality sintered metal filter cartridges made from stainless steel wire mesh offer excellent filtration with high strength, smooth pores, and resistance to high temperatures, making them ideal for industries like food, chemical, and aerospace.

Description

Sintered Metal Filter Cartridge Provides Excellent Filtration

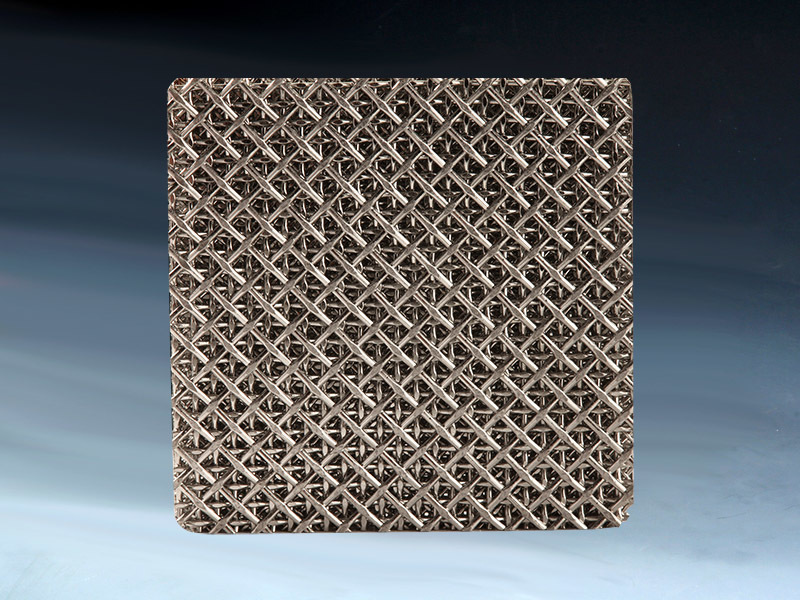

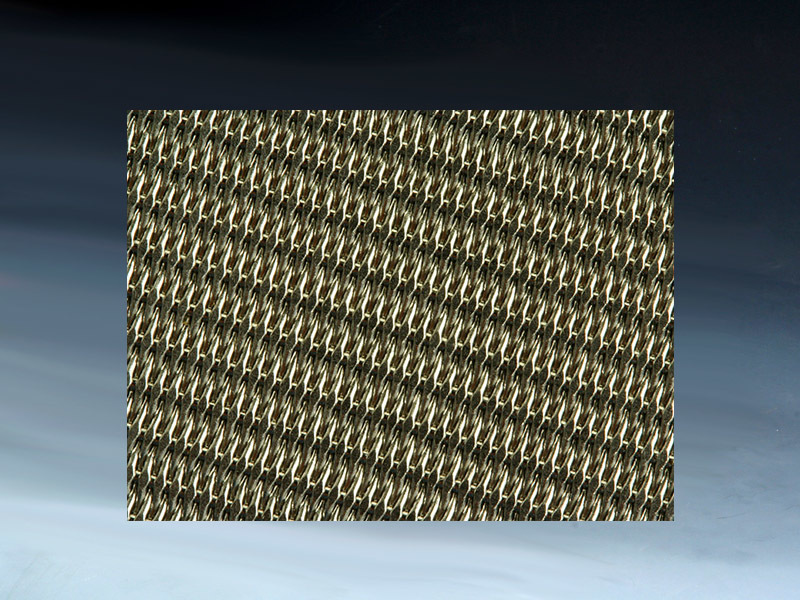

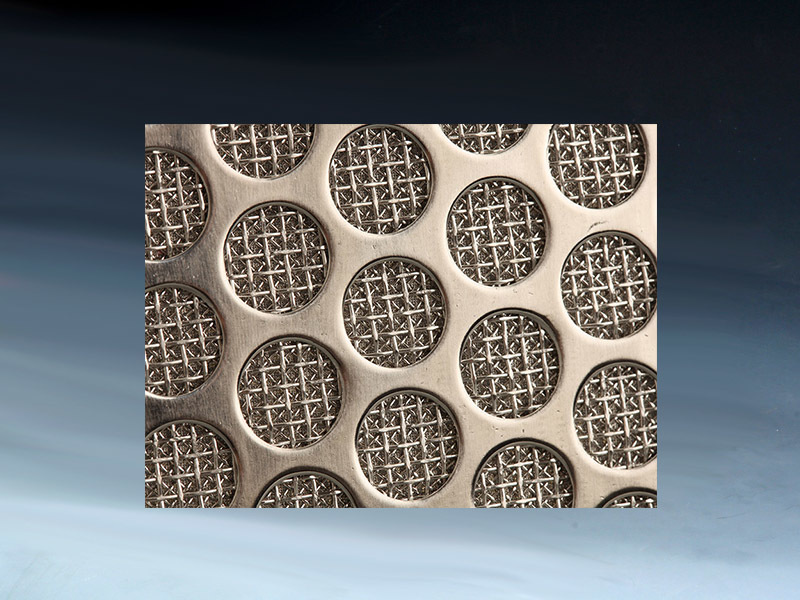

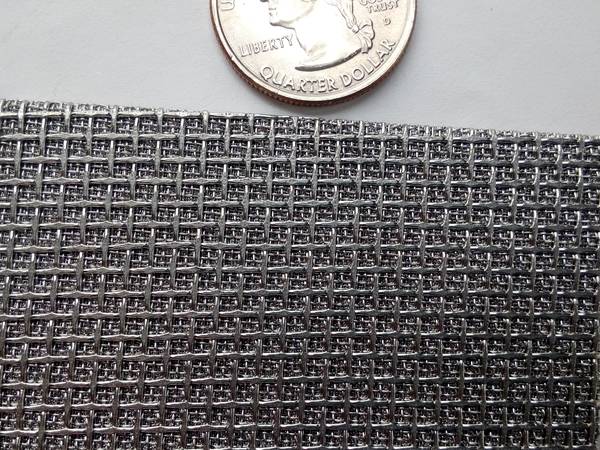

The sintered metal filter cartridge is made from stainless steel woven wire mesh or stainless steel fiber felt. It’s built by layering multiple wire meshes, sintering them together in a vacuum furnace, and then rolling them into a cylinder shape, with both ends welded together. To ensure its roundness and a smooth finish, a rolling seam welding process is used. This interwoven mesh creates a strong structure, solving issues of regular wire mesh like low strength and uneven hole shapes. It outperforms other filters like sintered powder and ceramic filters. Thanks to its excellent heat resistance, smooth pores, good airflow, and high dirt-holding capacity, this stainless steel filter cartridge is widely used in industries like food processing, environmental protection, chemicals, and aerospace.

|

|

|

|

|

|

|

|

|

|

|

|

Features

- Very strong and can handle high pressure.

- Great at resisting corrosion and very durable.

- Stable pore shapes with good flow of air or liquid.

- Can hold a lot of dirt and particles.

- Can work in a wide temperature range, from -200°C to 1000°C.

- Easy to clean and reuse, which extends its lifespan.

Specifications

- Standard Material: SUS 316 L, SUS 304, 316, 304, 317 L, 904 L, 321, titanium, and other alloys are available.

- Filter Rating: 0.2 microns to 300 microns.

- Standard Outer Diameter: 64 mm.

- Other Outer Diameters: 30 mm, 40 mm, 50 mm, 60 mm, 64 mm, 70 mm, 80 mm, 350 mm.

- Standard Inner Diameter: 28 mm.

- Lengths: 10″ (254 mm), 20″ (508 mm), 30″ (762 mm), 40″ (1016 mm), 60″ (1524 mm).

- Fittings: Double open end, single open end, double O-rings.

Applications

- Commonly used in industries like aerospace, oil, food, and metalworking for filtering liquids, gases, and solids, as well as for collecting gas samples and reducing noise.

- Helps distribute gas in fluidized beds.

- Used for washing and drying processes in the pharmaceutical industry.

- Applied in water treatment and gas filtration in the food and beverage sector.

- Used for filtering hydraulic or lubricating oil in the machinery industry.

- Used for filtering polymers in the chemical industry.