Sintered Square and Dutch Woven Mesh – Five Layers

Explore our five-layer sintered mesh made from stainless steel, featuring high strength, heat resistance up to 600°C, and precise filtration from 1 to 200 microns. Ideal for filtration in water treatment, gas distribution, and industrial applications. Custom sizes available.

Description

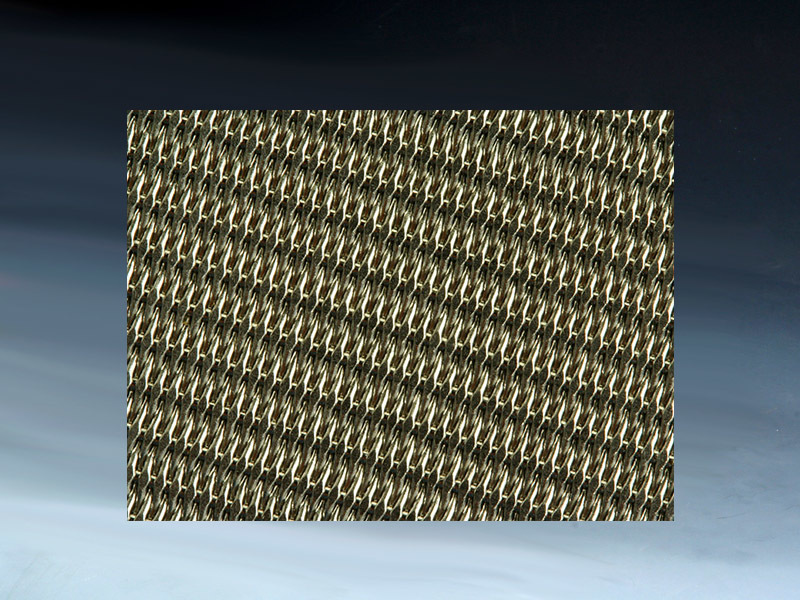

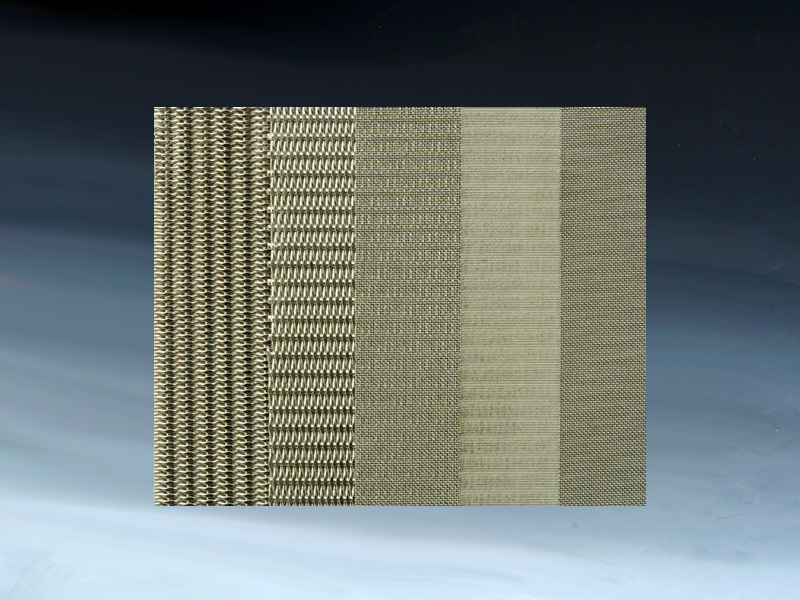

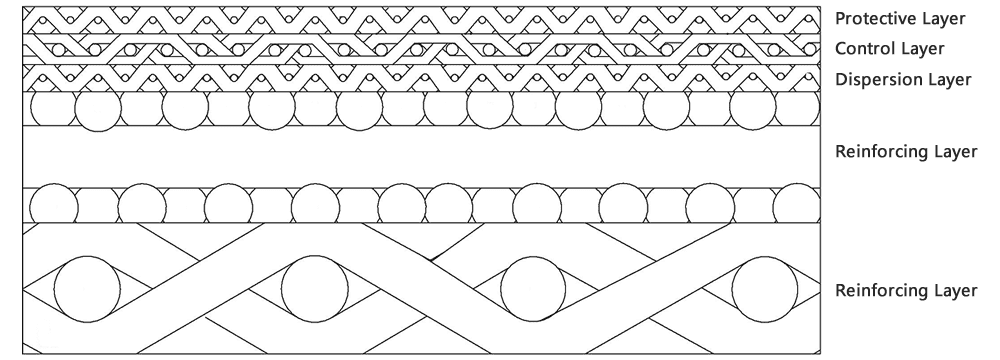

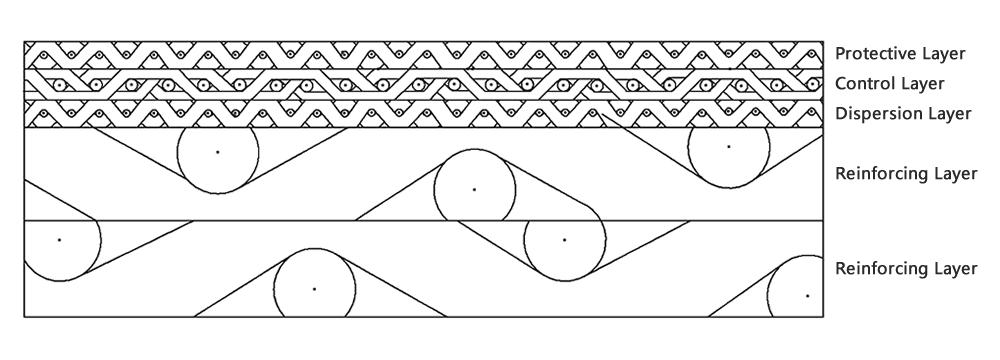

The five-layer sintered mesh is made by combining five layers of wire mesh with different sizes and thicknesses through a special process called sintering in a vacuum. This process bonds the wire mesh layers together, making it a stronger and more durable material. The result is a mesh with tiny holes that allow fluids or gases to pass through while filtering out unwanted particles.

By combining different layers, the mesh gets the best of both worlds: the fine layer offers excellent filtration, while the thicker layers provide strong support. The wires are fused at every crossing point, which improves the mesh’s ability to handle high temperatures and pressure.

This type of mesh is perfect for many uses, such as distributing gas, acting as vent covers, and filtering in industries like gas distribution, polyester production, and water treatment. Its unique combination of strength, permeability, and filtration makes it a reliable choice for many applications.

Specification

- Material: Made from Stainless Steel 316L, 304, 304L, 316, and other materials available upon request.

- Filtration Range: Filters particles from as small as 1 micron up to 200 microns.

- Heat Resistance: Can withstand temperatures up to 600°C.

- Standard Thickness: 1.7 mm.

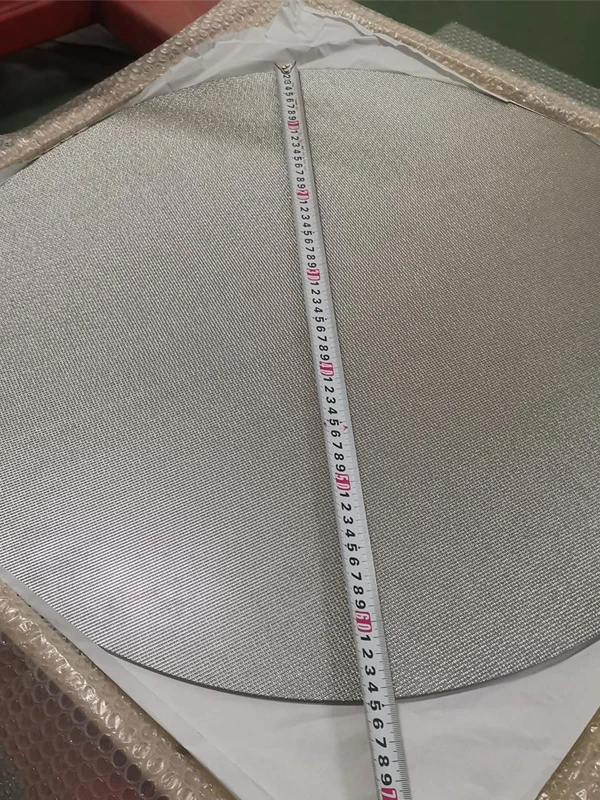

- Standard Sizes:

- 480 mm × 480 mm

- 480 mm × 980 mm

- 500 mm × 1000 mm

- 600 mm × 1200 mm

- 610 mm × 1219 mm

- 610 mm × 1250 mm

- 1000 mm × 1000 mm

- 1200 mm × 1200 mm

- Other custom sizes are also available.

- Maximum Size: 1219 mm × 1219 mm.

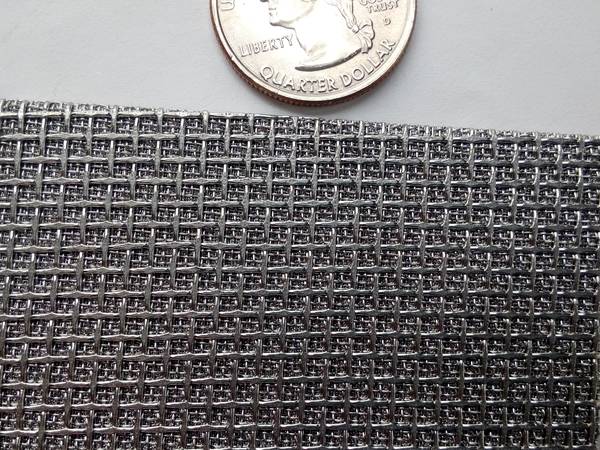

- Mesh Types: Available in both Sintered Dutch Woven Wire Mesh and Sintered Square Woven Wire Mesh.

Features

- Consistent Filtration: Maintains a stable filter quality even under high pressure.

- High Strength: Strong and durable structure.

- Easy to Shape: Can be welded, cut, and shaped into different forms with ease.

- Resistant to Corrosion and Wear: Good protection against rust and wear over time.

- Reusable: Easy to clean and can be used multiple times.

Five-layer sintered dutch woven wire mesh specification

| Code | Nominal filter rating (µm) | Structure | Overall thickness (mm) | Weight / sq.ft (kg) |

|---|---|---|---|---|

| MIC1L5 | 1 | 200 / 400 × 2800 / 200 / 12 × 64 / 64 × 12 100 / 400 × 2800 / 100 / 12 × 64 / 64 × 12 |

1.69926 | 1.1804 |

| MIC2L5 | 2 | 100 / 325 × 2300 / 100 / 12 × 64 / 64 × 12 | 1.69926 | 1.1804 |

| MIC5L5 | 5 | 100 / 200 × 1400 / 100 / 12 × 64 / 64 × 12 | 1.69926 | 0.2838 |

| MIC10L5 | 10 | 100 / 165 × 1400 / 100 / 12 × 64 / 64 × 12 | 1.69926 | 0.2838 |

| MIC15L5 | 15 | 100 / 165 × 1200 / 100 / 12 × 64 / 64 × 12 | 1.69926 | 1.1804 |

| MIC20L5 | 20 | 100 / 165 × 800 / 100 / 12 × 64 / 64 × 12 | 1.69926 | 1.1804 |

| MIC25L5 | 25 | 100 / 165 × 600 / 100 / 12 × 64 / 64 × 12 | 1.69926 | 0.2838 |

| MIC30L5 | 30 | 100 / 400 / 100 / 12 × 64 / 64 × 12 100 / 450 / 100 / 12 × 64 / 64 × 12 |

1.69926 | 1.1804 |

| MIC40L5 | 40 | 100 / 325 / 100 / 12 × 64 / 64 × 12 | 1.69926 | 0.2838 |

| MIC50L5 | 50 | 100 / 250 / 100 / 12 × 64 / 64 × 12 | 1.69926 | 1.1804 |

| MIC75L5 | 75 | 100 / 200 / 100 / 12 × 64 / 64 × 12 | 1.69926 | 0.2838 |

| MIC100L5 | 100 | 100 / 150 / 100 / 12 × 64 / 64 × 12 | 1.69926 | 0.2838 |

| MIC120L5 | 120 | 100 / 120 / 100 / 12 × 64 / 64 × 12 | 1.69926 | 0.2838 |

Note: 1. Porosity: 37%. 2. MIC: micron, L: layer.

Filtration property – five-layer sintered mesh

| Type | Air permeability (L/min.dm2) | Rating micron (µm) | Bubble point pressure (Pa) 8% |

|---|---|---|---|

| FP-05 | 200 | 2.5 – 7.5 | 5000 |

| FP-10 | 250 | 7.5 – 12.5 | 3700 |

| FP-15 | 350 | 12.5 – 17.5 | 2600 |

| FP-20 | 450 | 17.5 – 22.5 | 1950 |

| FP-30 | 550 | 27.5 – 35 | 1230 |

| FP-40 | 650 | 35 – 45 | 1020 |

| FP-50 | 750 | 45 – 60 | 860 |

| FP-70 | 900 | 60 – 80 | 690 |

| FP-100 | 950 | 80 – 120 | 630 |

Note: FP – filtration property, 05 – filter rating is five.

Specification – five-layer sintered square woven wire mesh

| Code | Structure | Thickness (mm) | Weight (kg/m2) | Porosity (%) |

|---|---|---|---|---|

| FSWM – 1.9 | 30 / Filter layer / 60 / 20 / 16 | 1.9 | 5.3 | 52 |

| FSWM – 2.5 | 80 / Filter layer / 30 / 10 / 8.5 | 2.5 | 8.8 | 55 |

Note:1. Filter rating varies from 2 µm to 200 µm, the filtration layer is selected as per customers’ need. 2. The porosity takes 20 mesh as criteria.

Application

The five-layer sintered mesh is commonly used for filtering polymers, food, water, cosmetics, pharmaceuticals, chemicals, and hydraulic fluids. Additionally, it’s applied in the fluidization of bulk materials in equipment such as wagons, conveyors, dryers, coolers, and storage silos.

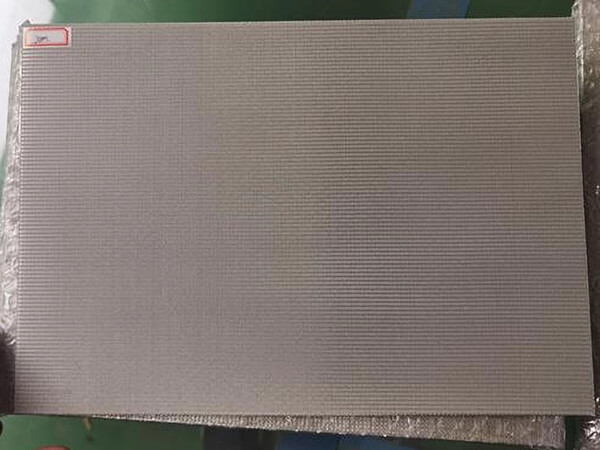

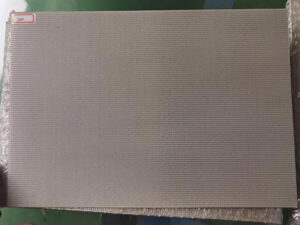

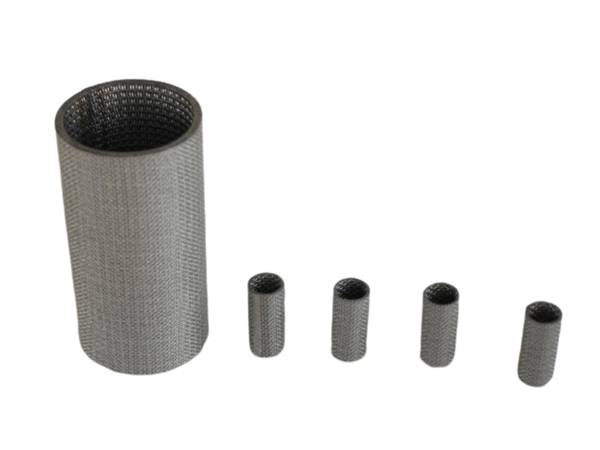

Product Showcase

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|