Sintered Mesh Laminate

High-strength sintered mesh laminates made from stainless steel or alloys, available in single or multiple layers. Custom designs tailored for stability, strength, and effective filtration across various industries.

Showing all 7 results

High-strength sintered mesh laminates made from stainless steel or alloys, available in single or multiple layers. Custom designs tailored for stability, strength, and effective filtration across various industries.

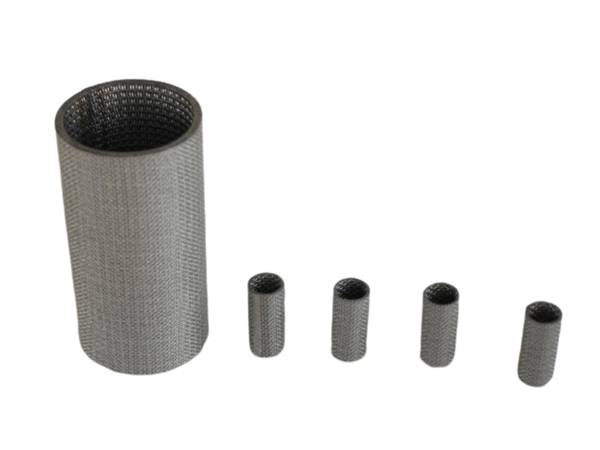

High-quality sintered metal filter cartridges made from stainless steel wire mesh offer excellent filtration with high strength, smooth pores, and resistance to high temperatures, making them ideal for industries like food, chemical, and aerospace.

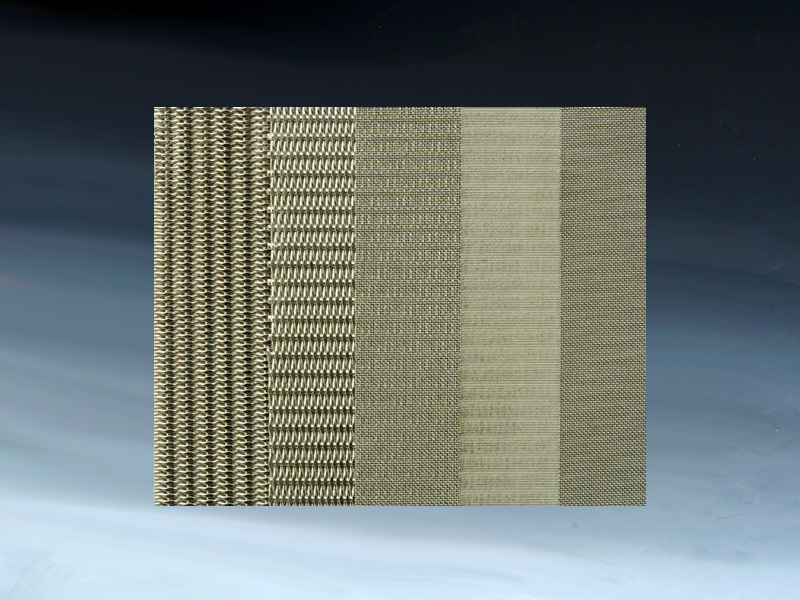

Explore our five-layer sintered mesh made from stainless steel, featuring high strength, heat resistance up to 600°C, and precise filtration from 1 to 200 microns. Ideal for filtration in water treatment, gas distribution, and industrial applications. Custom sizes available.

This is a widely used type of filter made from a combination of five layers of stainless steel wire mesh. The layers are joined together and transformed into a porous product by a process involving vacuum sintering, compression, and calendaring. This filter is versatile and has broad applications. Specifications available upon request.

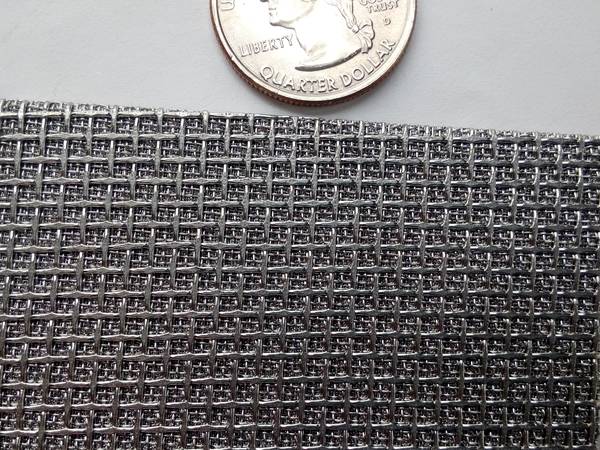

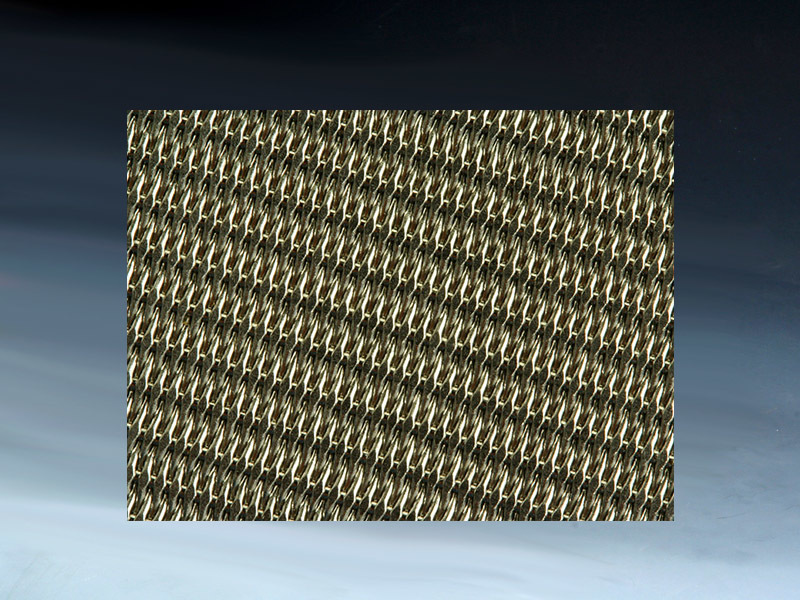

This type of mesh is created by sintering together multiple layers of simple woven square mesh. Because of the large openings between the mesh strands, the sintered mesh allows fluids to pass through easily, resulting in good permeability, low resistance, and high flow rates.

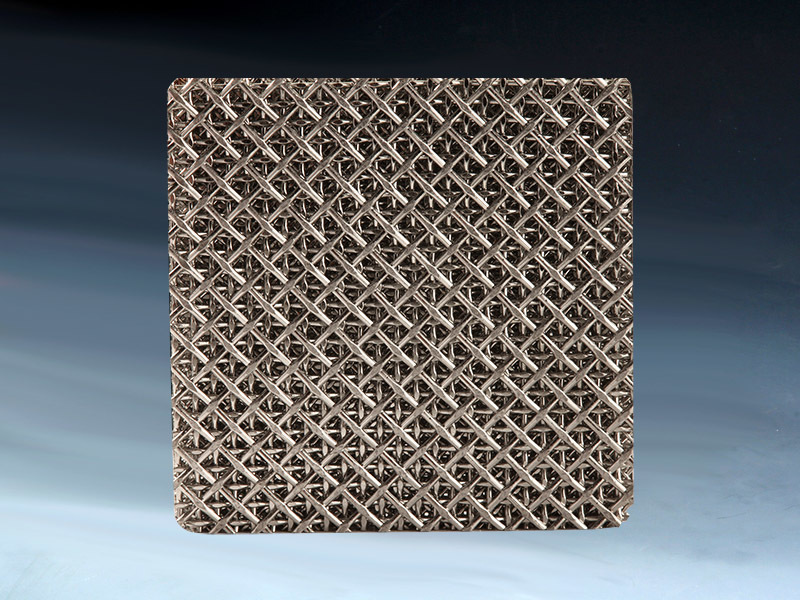

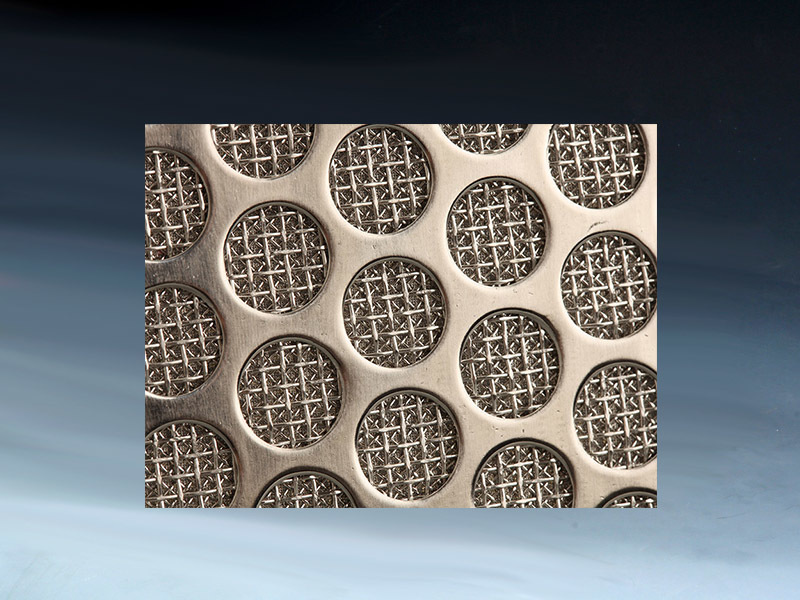

This filter is made by pressing a plate with layers of stainless steel mesh. The plate adds extra strength, making it useful in various industries like food, drinks, and water treatment.

Type D sintered wire mesh is created by layering 2 or 3 sheets of plain Dutch woven wire mesh with the same hole size. These layers are then vacuum sintered, expanded, and rolled flat. This process results in a mesh with consistent pore size and reliable airflow.

©2003-2024. Keeper Limited. All Rights Reserved.