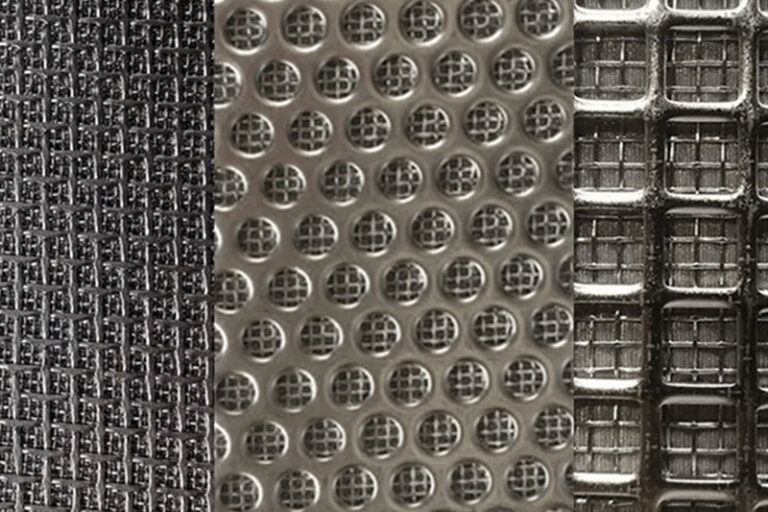

Stainless steel filter cartridges come in two main forms: pleated and cylindrical. This article highlights the features of stainless steel filters and compares the pleated and cylindrical varieties.

What is a Stainless Steel Filter Cartridge?

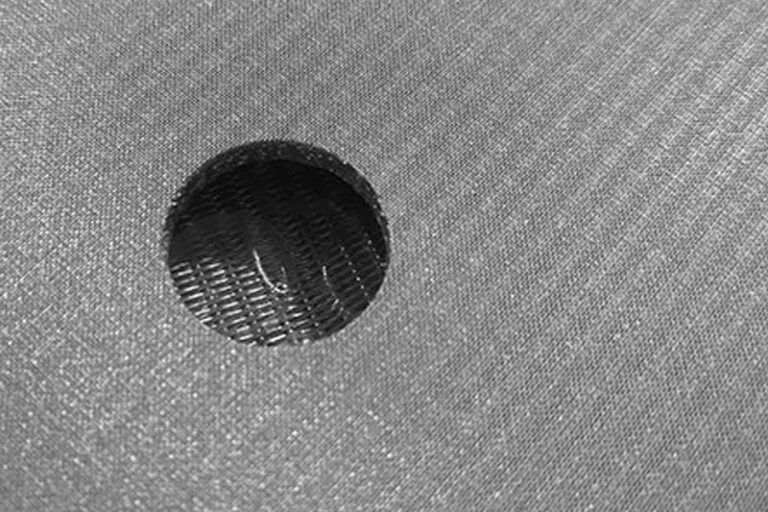

A stainless steel filter cartridge is a filter element made of stainless steel filter media and hardware, shaped like a tube or cylinder used as a cartridge.

Application Scenarios of Stainless Steel Filter Cartridges

Stainless steel filter cartridges excel in high-temperature and high-pressure environments, unlike most non-metallic filter cartridges. They can withstand various cleaning methods, such as high-pressure water washing, chemical baths, ultrasonic cleaning, heating, and even incineration. This makes them ideal for automatic filters with backwashing or backflushing capabilities.

Advantages of Stainless Steel Filter Cartridges

Compared to non-metallic filter elements, stainless steel filter cartridges offer several advantages:

- Suitable for high temperatures

- Can withstand high pressures

- Washable and reusable

- Ideal for automatic backwashing/backflushing

- Anti-static properties

- Efficient heat transfer capabilities

Disadvantages of Stainless Steel Filter Cartridges

Despite their benefits, stainless steel filter cartridges have some drawbacks:

- Weight: Stainless steel is heavier than non-metallic materials.

- Cost: Stainless steel filters are more expensive than most non-metallic counterparts.

- Corrosion Resistance: While grades like 316L have good corrosion resistance, they may not match certain non-metallic materials like PTFE in severe conditions such as hydrochloric acid (HCl) corrosion.

- Limited Micron Rating: The minimum micron rating for stainless steel filters is currently around 0.5 microns and cannot be extended to extremely small sizes like 0.01 microns. Therefore, stainless steel filters are primarily used for filtering in the micron and millimeter range.