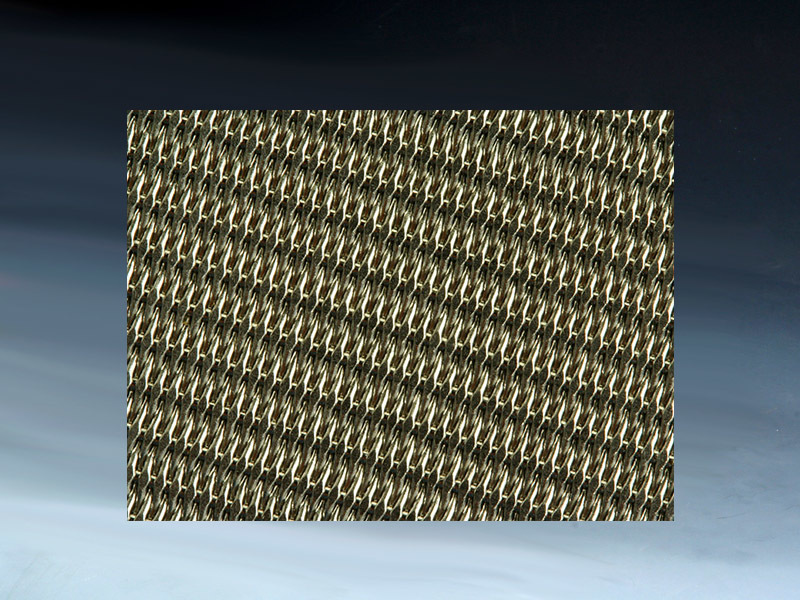

Type D sintered mesh

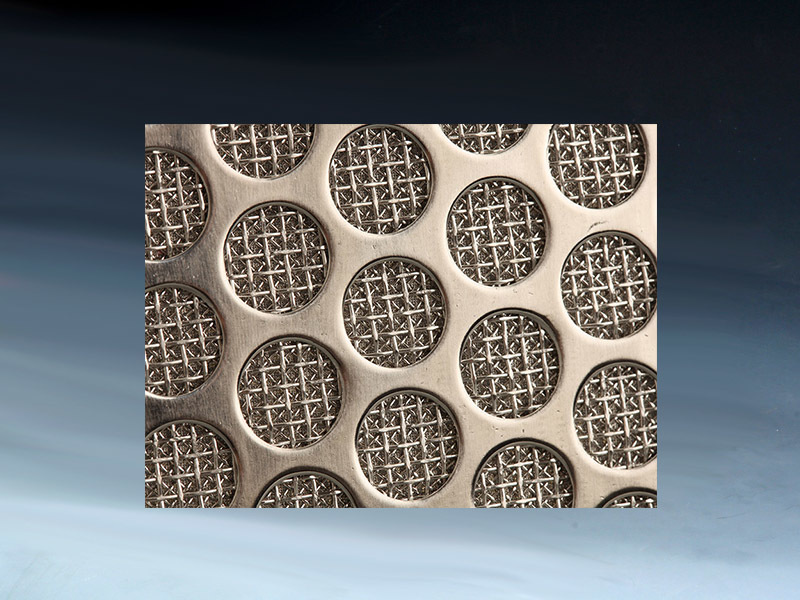

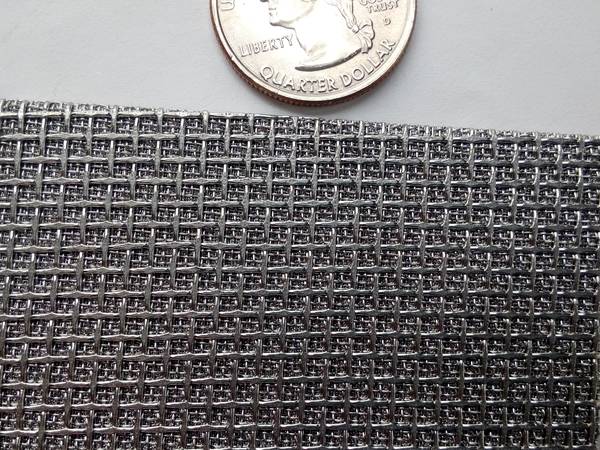

Type D sintered wire mesh is created by layering 2 or 3 sheets of plain Dutch woven wire mesh with the same hole size. These layers are then vacuum sintered, expanded, and rolled flat. This process results in a mesh with consistent pore size and reliable airflow.

Description

Type D Sintered Mesh

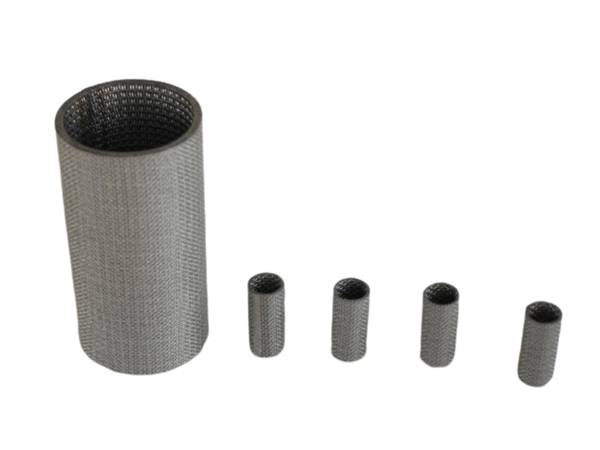

Type D sintered wire mesh is composed of 2 or 3 layers of plain Dutch woven wire mesh with the same hole size, overlapped and stacked together. Following this, the mesh undergoes a process of vacuum sintering, inflation, and calendering. The result is a material with an average pore size and consistent breathability. It finds extensive applications in powder transportation, laboratory liquid beds, dryers, and coolers.

Material

The standard materials for Type D sintered mesh include SS304, SS316, and SS316L. Additionally, special alloy steels such as Hastelloy, Monel, and Inconel are also acceptable based on customer requirements.

Size

Standard sizes for Type D sintered mesh are 500x1000mm, 600x1200mm, 1000x1000mm, and 1200x1200mm. Custom sizes within this range can be accommodated upon request.

Application Range

For over 18 years, Keeper’s senior technical team has been providing metal filter technology and design advice to customers across various industries. They specialize in tailoring solutions to meet diverse customization needs. Type D sintered mesh finds applications in:

- Oil industry

- Chemical industry

- Pharmaceuticals

- Power plants

- Aerospace

- Food and beverages

- Water treatment